EV Batteries and Energy Storage

What is Energy Storage and Batteries and Why Does it Matter?

Energy storage and batteries are critical components in the electrical grid. Battery Energy Storage Systems (BESSs) enable producers to collect energy from inconsistent power generation sources like solar and wind and feed the network at a more consistent rate or at high demands. Energy Storage also enables users to collect energy, usually at low demand for lower costs, and use the energy when they need it. This could be at energy distribution networks, balancing the grid when needed, large energy consumption sites like retail stores, an emergency power source for companies and homes, or mobile energy consumption like electric vehicle (EV) batteries.

Increased power consumption in EVs, electrified appliances, the internet of things, and massive data collection and processing, makes providing a consistent and reliable energy source for these systems paramount.

Why Boyd for Battery Solutions?

Our lightweight, high performance sealing solutions help you design larger batteries with greater power density.

We ruggedize batteries to withstand harsh environmental and road conditions for energy storage and EV batteries with extended life and range.

Streamlined, multi-functional solutions that seal, insulate, and protect integrate system design to help reduce weight, create additional design space, and maximize energy creation, efficiency, and storage capacity.

Our quick design cycles and fast prototyping help you rapidly iterate designs, creating a competitive advantage in speed to market and enabling you to introduce new products faster for earlier market access.

We design solutions for simplified customer assembly, design for manufacturing (DFM) throughput, and material optimization.

We give you greater design flexibility with manufacturing capabilities that combine materials from a variety of vendors, creating optimized multilayer material configurations.

EV Batteries and Energy Storage Resources

The Boyd Difference for an EV Battery Pack

We know safety and reliability. We’re also experts at maximizing power density, energy utilization, recovery, and efficiency in applications. We’ve proven reliability and safety are at the forefront of our design and manufacturing support for transportation, aerospace, and defense markets for over 60 years, driving innovation to make our technologies lighter and more compact. And we’re blending this heritage with innovative manufacturing processes, materials, and technologies from our experience in advanced industries to enhance EV battery pack component design and technology safely and efficiently.Boyd’s Battery Heritage

- 1 million + EV battery seals installed in today’s leading electric vehicles.

- 2 million + eMobility battery component installations.

- More than 60 years of field-proven performance and over 1 billion units shipped in transportation, aerospace, and defense applications for trusted reliability in markets where safety is a key concern.

Ruggedize Batteries to Withstand Environmental Exposure and Consumer Use

Energy storage applications and electric vehicle batteries operate in some of the world’s most demanding and extreme environments. To prolong safe and reliable battery performance at maximum efficiency, designs must be strategically ruggedized to protect against extreme heat, cold, UV exposure, wind, sand, rain, road vibration, and sudden impact. Having an adequate seal for packs and modules protects the battery and its cells against liquid, gas, particle, and contaminant intrusion or exposure to prevent catastrophic failures and prolong battery life.Sudden Impact Battery Protection and Compression Pads

Batteries need to be protected against sudden impact, vibration, and swelling forces that can come from mechanical movement, temperature cycling, sound, wind, or other environmental factors. Electric vehicle batteries experience additional extreme environments from harsh road conditions and collision impact from accidents and near-misses. Boyd’s compression pads layer between battery cells to compensate for swelling forces, manage cell expansion and contraction of cell tolerance stack, and act as an impact protection barrier from mechanical movement resulting from collisions and vibration. Ruggedized impact-absorbing battery seals help you minimize the detrimental impact to batteries and reduce maintenance demand and consumer warranty costs while enhancing battery safety.

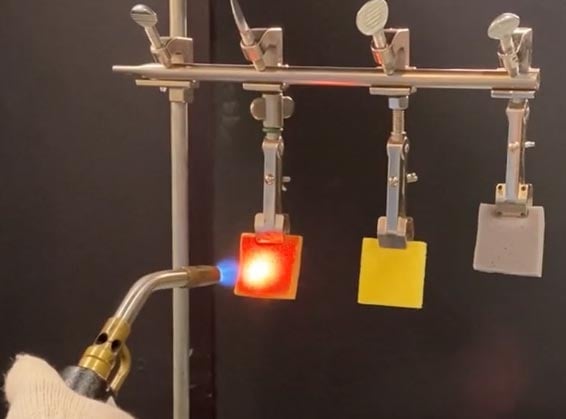

Battery Fire Isolation and Protection

Modern battery design is optimized to prevent fire from ever occurring. But in the rare event of a catastrophic battery failure with fire, proactive safety design integrates high performance and reliable fire isolation. Fire isolation can be achieved many different ways and at different battery system levels for primary and secondary fire isolation performance. Battery cells and modules can be wrapped with electrically isolating high performance films. These lightweight, rugged insulation layers wrap battery cells to prevent spart voltage between internal critical components that can lead to device shorting or fire. Using the highest flame-rated FR V0 isolation films helps to prevent fire from occurring, or isolating it at the primary battery cell level in the unlikely event a cell combusts.

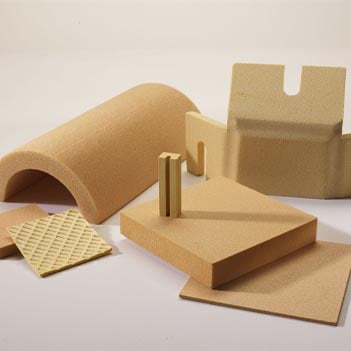

SOLIMIDE® Battery Insulation and Protection

SOLIMIDE® is a fire resistant, ultra-lightweight, non-toxic foam that can maintain peak performance at both high and low temperature extremes. It is exceptionally flame resistant and used as a flame barrier in many critical applications. SOLIMIDE® will not ignite or combust under continuous long term direct exposure to flame, emits zero toxins and very little smoke. It offers traditional foam performance characteristics like compressibility and vibration damping. It’s also non-wicking with high hydrolytic stability, meaning it won’t retain water or water weight and can withstand long exposure to liquids. When applied in a battery pack, it acts as secondary fire protection at the battery pack level, isolating flame and fire while absorbing both mechanical vibration and acoustics for safer, quieter, more reliable batteries.

Preventing Li-ion Battery Thermal Runaway

Good temperature management of lithium-ion battery cells with additional back up safety features help to prevent battery thermal runaway events or respond safely and swiftly if they occur. Thermal runaway prevention starts with optimized design but also requires components that protect against thermal runaway propagation. Multi-functional, complex battery component solutions designed for cell-to-cell application absorb impact, vibration and movement, dissipate cell heat, and act a flame or heat barrier and isolator if a catastrophic event were to occur. Enable your designs to proactively and safely prevent thermal runaway events by managing vibration, movement and friction, and quickly isolate extreme heat or fire in the unlikely event battery safety design features fail to prevent cell-to-cell propagation. Highly integrated thermal runaway prevention assemblies feature cooling fins or heat spreaders with compression pads and flame-rated electrical insulation to isolate li-ion battery cells. Prevent, protect, and isolate battery storage thermal runaway and EV battery thermal runaway.

Top Three Causes of Thermal Runaway and How to Prevent Them

View transcript

Maximize BESS Performance with Boyd’s Sealing and Cooling Technologies

(View transcript)

Ruggedize Batteries to Withstand Environmental Exposure

(View transcript)

How to Cool and Protect EV Batteries Against Collision and Thermal Runaway

(View transcript)

Global Network & Local Support

Boyd maintains ISO 9001 and IATF 16949 certified manufacturing operations across three continents to assure our energy storage and eMobility components exceed the rigorous demands for quality management systems with adept regional support. Boyd’s customer focus and relationship management culture are aligned with the most demanding QMS system processes. By optimizing processes, organization, and efficiency, we reduce costs, increase yield rates with effective management and assembly processes, all while providing our customers the highest quality products.

Solve Sustainability Regulations of the Future

Boyd’s globally available, in-region ISO 14001 certified manufacturing operations and longstanding partnerships with eMobility, electric vehicle, hybrid electric vehicle, autonomy, and energy storage innovators influence how we exceed rigorous safety and regional environmental requirements, anticipate evolving consumer needs, and solve sustainability regulations of the future.

Trusted Innovation in eMobility | EV Battery Cooling and Thermal Runaway Solutions

eMobility Solutions | EV Thermal Runaway Protection |EV HMI and Battery Cooling Technology

Benefits of EV Batteries and Energy Storage:

Collect energy for rapid battery charging for electric vehicles.

Purchase energy at lower demand times for better pricing.

Store energy for emergency consumption, especially for critical locations and systems like hospitals and data centers.

Improves the reliability of power production of sustainable sources like wind farms or solar farms.

Balance grid production and demand, especially during peak operating hours.

EV Batteries and Energy Storage Challenges:

Supporting equipment and protective materials reduce available volume for battery cells and reduces energy density.

Renewable on-site energy storage systems are located at the solar or wind farms, which can be in remote locations. This can limit system maintenance and requires highly reliable systems for ongoing usage.

EV batteries must meet demanding safety standards for passenger safety, which includes collision protection and fire-resistant materials to increase egress time in emergencies.

Every gram counts in extending EV battery range, so protection and cooling systems must use lightweight, yet reliable solutions.

Leverage Boyd’s 15+ years of battery expertise to enhance your product.

Key Battery and Energy Terms to Know

| Term | Definition |

|---|---|

| Seals and Gaskets | Seal battery packs, battery modules, and battery covers against temperature impact, air, dust and water ingress. Optimize performance, waterproof and seal while considering compression set and force deflection, NVH and other mechanical factors. |

| Venting Films and Seals | Control internal battery assembly or pack pressure, moisture, and other environmental factors. |

| EMI Shielding | Reduce electronic malfunction susceptibility in battery packs and modules by blocking unwanted external electromagnetic waves. |

| Multilayer Thermal Runaway Protection | High temperature, fire resistant foams and films to shield, block and suppress flame between battery cells and modules. |

| Compression and Tolerance Pads | Manage expansion and contraction of battery cell tolerance stack and temperature cycling. |

| Electrical Insulation and Cell Wrapping | Insulation layers wrap battery cells and modules to prevent spark voltage between internal critical components that can lead to device shorting or fire. |

| Dielectric Adhesives for Busbars | Protect flexible printed circuits in battery assemblies to extend device lifetimes. |

| Battery Liquid Cold Plates | Ultra lightweight liquid aluminum cold plates provide Robust Structural Support (RSS) for today’s highest performing battery modules and packs. Direct liquid cooling interface between the liquid cooling system and battery packs. |

| Thermal Interface Materials (TIMs) | Facilitate heat transfer between the cooling plate and battery module, moving heat away from sensitive components. TIM helps to minimize resistance of heat flow into, through and out of an interface. |

| Cell-to-Cell Bonding | Pressure Sensitive Adhesives bond pouch and prismatic cells together to enhance structural integrity in Battery pack assemblies. |

| Door-Mount Chillers | Through-door mount chiller that provides liquid cooling in harsher atmospheric conditions. |

Battery FAQs

Are there eco-friendly battery cooling solutions?

Yes, eco-friendly battery cooling solutions focus on using sustainable materials, energy-efficient methods, and environmentally friendly refrigerants. These solutions reduce energy consumption, minimize carbon footprints, and lower the environmental impact of cooling systems while maintaining high performance.What role does cooling play in battery safety?

Cooling plays a crucial role in battery safety by preventing overheating, which can trigger thermal runaway, fires, or chemical reactions. By maintaining a stable temperature, cooling systems reduce the risk of dangerous temperature spikes and ensure safe operation under various conditions.

What is the role of phase change materials (PCMs) in battery cooling?

Phase change materials (PCMs) absorb and store excess heat during high-temperature periods, maintaining a stable temperature by changing phase, typically from solid to liquid.EV Battery Solutions

View our 3D interactive tool to explore Boyd’s EV battery solutions and how we drive multifaceted innovation. Click the image or the button below to immerse yourself with our EV battery solutions!Closing

1 million + EV battery seals installed in today’s leading electric vehicles. 2 million + eMobility battery component installations. More than 60 years of field-proven performance and over 1 billion units shipped in transportation, aerospace, and defense applications for trusted reliability in markets where safety is a key concern.Boyd’s Battery Thermal Heritage

- One of the first to introduce door-mounted chiller liquid cooling systems to integrate into storage applications for batteries.

- 30 billion + field hours with zero leaks in liquid cooling systems to reliably maximize battery thermal performance.

- 500K+ liquid cold plates installed in the field with zero leaks for safe direct liquid cooling interface to battery modules that boosts power density.

Battery Cooling and Isolate Battery Fire Risk to Maximize Efficiency and Safety

Batteries are the most integral part of an electric vehicle or energy storage installation with charge cycling, storage capacity, and range being a primary concern to adoption. Thermal density limitations are often a key contributing factor to innovation in this space. Boyd’s liquid cooling systems and cold plates enable smaller, lighter battery thermal systems; creating more design space for more powerful batteries with faster charge cycles and more efficient utilization of energy. Electric vehicles specifically benefit from EV batteries that are more reliable and have greater driving range per charge.Battery Cooling FAQs

What is battery cooling, and why is it important?

Battery cooling manages battery temperatures in electric vehicles and energy storage systems to optimize performance, safety, and lifespan. It prevents overheating, maintains consistent energy output, and enhances battery durability in demanding conditions.Why do batteries need cooling?

Batteries need cooling to prevent overheating, which leads to reduced performance, shorter lifespan, and safety risks. Cooling systems regulate temperature during charging, discharging, and operation, ensuring the battery performs efficiently and reliably under various conditions.What are the common methods of cooling batteries?

Air cooling, liquid cooling, and immersion cooling are common methods for managing battery temperatures. Air cooling circulates air around batteries using fans, while liquid cooling transfers heat by circulating coolant through channels or plates. Immersion cooling submerges batteries in dielectric fluid, enabling direct heat transfer and superior thermal management.How does liquid cooling work for battery cooling?

Liquid cooling manages battery temperatures by circulating coolant through channels, plates, or tubes in direct contact with the battery pack. The coolant absorbs heat during operation and transfers it to a heat exchanger, which dissipates the heat into the environment.What are the advantages of air cooling for battery systems?

Air cooling provides a simple, cost-effective way to manage battery temperatures. Fans circulate air to maintain optimal performance, keeping the system lightweight and easy to integrate.Are there cooling solutions designed for specific types of batteries?

Yes, cooling solutions are tailored to specific battery types, such as lithium-ion, solid-state, and lead-acid batteries. Each battery type has unique thermal management needs based on its size, chemistry, and application. Customized cooling systems optimize performance, safety, and lifespan for each battery type.How does battery cooling affect the performance of electric vehicles (EVs)?

Battery cooling impacts the performance of electric vehicles (EVs) by maintaining an optimal battery temperature. This ensures efficient energy output, faster charging, and a longer driving range. Effective cooling prevents overheating, reduces energy loss, and extends battery lifespan, enabling EVs to perform reliably in varying conditions.What are the challenges of cooling high-capacity batteries?

Cooling high-capacity batteries presents challenges due to the significant heat generated during charging and discharging. Larger batteries produce more heat, requiring efficient and precise cooling solutions. Additional challenges include managing temperature uniformity across the battery pack, avoiding thermal hotspots, and ensuring safety and reliability.Can battery cooling systems improve battery life?

Yes, battery cooling systems improve battery life by maintaining optimal operating temperatures. They prevent overheating and reduce temperature fluctuations, minimizing stress on the battery and preserving its capacity and performance.What are the maintenance requirements for battery cooling systems?

Battery cooling systems require regular maintenance to maintain optimal performance. This includes checking coolant levels, inspecting pumps and fans, cleaning heat exchangers, and monitoring system components for wear or damage. Regular maintenance prevents system failures, ensures efficient cooling, and extends the lifespan of both the cooling system and the battery.How do cooling systems impact the design of battery-powered devices?

Cooling systems impact the design of battery-powered devices by influencing size, weight, and component layout. Designers integrate efficient cooling solutions to manage heat without compromising performance or battery life.Can battery cooling systems be retrofitted to existing devices?

Yes, we can retrofit battery cooling systems into existing devices. By designing compatible solutions, we integrate cooling systems into older models without major redesigns. Retrofitting improves performance, extends battery life, and enhances safety, especially in devices with high energy demands or those operating in challenging conditions.Have questions? We’re ready to help!