Bonding and Adhesive Systems

High performance adhesives and bonding solutions are specialty materials that can be challenging to handle. Boyd’s rotary die-cut process innovation, material expertise, and clean room environments enable us to construct advanced adhesive solutions to help bond displays with optically clear adhesives, protect wounds with medical grade adhesives, or create lasting bonds with high adhesion tapes.

What Goes Into Making Advanced Display Solutions?

(View transcript)

Medical Wearable Adhesive

Critical and High Performance Bonding and Adhesive Systems

Bonding and adhesive systems are highly engineered materials that include a broad range of adhesive tapes, optically clear adhesives, epoxies, or rubbers (OCA/OCR) and pressure sensitive adhesive (PSA). These materials typically adhere a variety of substrates together or bond components into an assembly. Adhesive and bonding materials are essential components to high performance in nearly every industry.

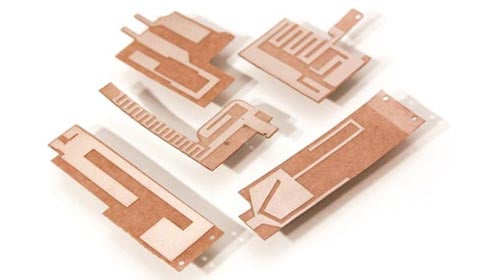

Boyd has access to the broadest portfolio of expert adhesive and tape suppliers in the world and can additionally laminate custom formulations for your application. Our ability to mix and match materials with our world-class precision converting processes like rotary die cutting, kiss-cutting, slitting and more can create custom composite tape solutions for any application.

Have a Question?

Decades of Experience Designing Custom Solutions

Boyd is an adhesives expert with decades of experience designing custom solutions, such as medical stick to skin disposables, custom wearable medical device assemblies, medical tape converting and advanced rearview mirror display stackups that feature adhesives and tape for quick and easy assembly. Boyd engineers utilize a series of key parameters to identify the best adhesive system for an application. The success or failure of an adhesive relies on variables such as mating substrates, polymer type, surface contact, dwell time or potential environmental exposures. Failing to consider all aspects of the application can lead to insufficient pull strength, impact resistance, inadequate temperature resistance and product lifetime.

High Volume Precision Rotary Converting at Boyd

Boyd is well versed in designing and manufacturing a variety of cutting-edge solutions with ultra-tight tolerances laminating multiple material layers for complex assemblies and fabricating value-added solutions formatted for automated assembly equipment with registration control for pick and place in reel-to-reel presentation of parts or individually packed.

Display and Optically Clear Adhesives

Increase customer accessibility with LCD, LED, and OLED screens. Supporting components help deliver maximum functionality, performance, and optics. Boyd display technologies and optically clear adhesive precision converting expertise generate cost effective, tight tolerance, registration controlled, high performance display solutions.

Tapes

Tapes are available in a wide range of options like pressure-sensitive adhesive (PSA), single or double sided tape, or other formulations to bond specific, similar, or dissimilar materials. Full coverage, island placement adhesive, and selective coverage adhesive designs allow Boyd to optimize material utilization and product performance to your specifications.

Medical Grade Adhesives

Boyd specializes in medical grade adhesives with decades of expertise. Products range from consumer medical adhesives to industrial grade wound care solutions with drug delivery. Boyd is a world leader in wound care and medical disposables with expertise in skin contact adhesives and tapes, one-time disposables, and repeat-use disposables.

Have questions? We’re ready to help!