Automation

What is Automation and Why Does it Matter?

Automation utilizes technology, tools, and systematic procedures to execute tasks with limited human involvement. Organizations leverage automation to optimize repetitive and complex tasks enhancing efficiency, accuracy, and overall productivity. Automation equipment is the mechanical hardware or systems that assist in fabrication, assembly, testing and quality assurance, or packaging.

Why Boyd for Automation Solutions?

Get your product to market quicker with prototypes created quickly and easily changed without expensive tooling for design samples, presentations, or proof-of-concept.

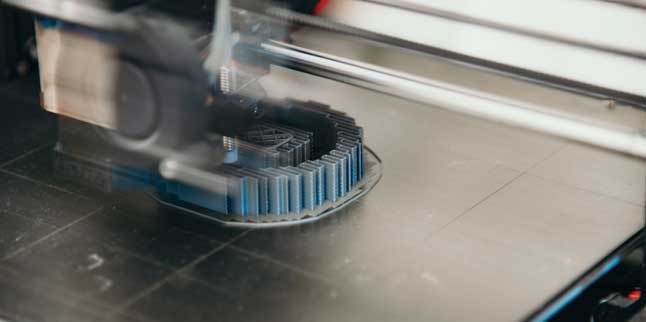

Meet tough design specifications and realize complex part geometries including undercuts, re-entrant angles, hollow spaces, and more with Boyd’s 3D printing options.

Eliminate waste iterating and refining product designs quickly with small 3D printed production runs.

Integrate thermal and mechanical systems into a single component for simplified assembly and reduced costs.

Economical technologies with faster prototyping, higher production volume, and shorter lead times.

Examples of Automation

Industrial manufacturing harnesses automation to improve efficiency, precision, and control across a range of applications, from robotics to cutting-edge techniques such as 3D printing and laser processing. Semiconductor automation test equipment expedites the validation process and reduces in-field component failure. Motor drives play a pivotal role by actuating robotic arms for welding, painting, and assembling components with remarkable accuracy and efficiency, especially in the automotive industry. Similarly, additive manufacturing uses automated systems to craft intricate and complex 3D objects, achieving a high degree of precision.

The Boyd Difference for Automation

Boyd’s Broad Technology Portfolio for Integrated Automation Equipment Solutions

Boyd is at the forefront of innovation, seamlessly integrating complex thermal management and engineered material solutions into automation equipment platforms. We leverage these advancements to develop intricate designs and rapidly prototype cutting-edge solutions. Our capabilities extend from creating components such as heat pipes, vapor chambers, liquid cold plates, heat exchangers, and heat sinks with unique geometries, to producing silicone and plastic products.

Facilitate Uninterrupted Automation with Effective Air-Cooling Solutions

Elevate the efficiency of automation systems and facilitate seamless operations by leveraging the benefits of automated processes and integrating motor drive enclosures or chassis equipped with advanced air-cooling technology. Air cooled enclosures maintain precise temperature control to minimize overheating, reduce energy consumption, and mitigate risks to longevity and performance for peak motor drive efficiency.

Integrate multi-functions into one component with Boyd’s Sealing and Protection Solutions

Boyd’s environmental sealing solutions keep dust and debris out of sensitive equipment, manage or direct airflow, guard against EMI shielding, absorb mechanical or acoustic energy, and seal surfaces against the elements and consumer use environments. Our electronic enclosures and chassis integrate functions into one component including sealing, thermal management, and shielding for efficiency.

Optimize Overall Efficiency with Boyd’s Optical Encoders

Optical encoders provide crucial position and motion feedback to empower systems to operate with the utmost accuracy, ensure seamless performance, and optimize overall efficiency. Achieve precision, accuracy, and efficiency by seamlessly integrating Boyd’s optical encoders into your automation processes.

Enhance User Experience with Comprehensive Human Machine Interfaces and Graphic Solutions

Human Machine Interfaces are critical aspects of your product design and its user experience. From mechanical elastomer buttons and membrane switches to more advanced capacitive switches and touchscreens, Boyd has the technology and design experience to support your automation interface needs.

Boyd’s Graphics Solutions

Boyd integrates innovative manufacturing methodologies and Pantone color matching on thin-film plastics for durable and dependable, long-term graphic overlay and electrical insulation performance with UL 94 flame rated solutions. We simplify component complexity and provide a dependable outcome by integrating branding, vital information communication, and electrical insulation into a single, top-quality solution.

Human Machine Interface Solutions for the Automotive Industry

(View transcript)

What is Inside Advanced Display and Touchscreen Solutions?

(View transcript)

Global Network and Local Support

Boyd operates over 40 ISO 9001 certified manufacturing facilities spread across three continents. Our commitment to excellence goes beyond mere compliance, we surpass customer expectations by adhering to the most stringent quality management systems (QMS processes). We focus on refining processes, enhancing organizational efficiency, and executing impeccable management and assembly procedures.Benefits of Automation

Enhance efficiency and minimize downtime with automated systems that operate reliably and consistently.

Ensure uniform output and reduce variability in products or services by consistently following predefined procedures.

Enable quick responses to changing conditions or customer demands, ensuring agility in competitive markets.

Attain scalability to accommodate changes in demand without significant operational disruptions.

Enable innovation and new opportunities tackling intricate tasks that may be beyond the capabilities of manual labor.

Free human workers from monotonous, repetitive tasks, leading to increased job satisfaction and creativity.

Optimize resource usage and reduce waste, contributing to sustainable practices through automation.

Enable quality checks and inspections throughout the production process, ensuring consistent product quality.

Automation Challenges

Maintenance and Upkeep: Automated systems require regular maintenance and updates to ensure they operate optimally. Failing to maintain automation systems leads to downtime and decreased efficiency.

Technical Challenges: Automation systems rely on advanced technology, and occasionally encounter technical glitches, software bugs, or compatibility issues that need prompt resolution.

Integration Complexity: Integrating different automation components, systems, and software from various vendors is intricate, leading to interoperability issues.

Closing

30 billion + field hours with zero leaks in liquid cooling systems to reliably maximize performance

Quiet solutions reduce environmental noise pollution for safer operations

Have questions? We’re ready to help!