Two Phase Cooling

Boyd’s expertise in two-phase cooling spanning over 50 years enables us to create some of the most reliable thermal management solutions that can last upwards of 20 years. Our expertise in innovating, designing, and manufacturing high quality heat pipe assemblies, vapor chamber assemblies, and thermosiphons leverage the passive heat transport of two-phase cooling systems enable us to cool some of the most demanding applications.

Two Phase Enhanced Air Cooling for Power Electronics

(View transcript)

Innovative Two Phase Cooling Solutions that Meet the Most Stringent Requirements

For over 50 years Boyd has pioneered the development and commercialization of two phase cooling, playing an integral role in the advancement and use of heat pipes, vapor chambers, and thermosiphons. Boyd’s exceptional engineering, manufacturing, and testing capabilities enable innovative solutions that can meet the most stringent requirements, from the challenges of medical applications to the rigors of space and maritime devices.

Have a Question?

Decades of Experience in Research and Development

With decades of experience, dedicated resources for research and development, and design centers specially equipped for the development of two phase solutions, Boyd is uniquely positioned to tackle any thermal challenge. From simple embedded heat pipes to extraordinary two phase thermal systems utilizing multiple advanced technologies and materials, Boyd offers the full range of integrated solutions.

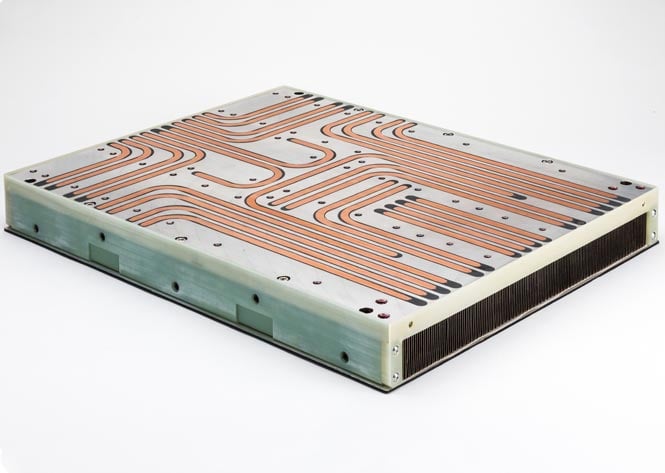

Heat Pipes and Heat Pipe Assemblies

Boyd dedicated to every aspect of heat pipe design and production, from R&D to high volume production of integrated assemblies, like loop and high temperature heat pipes. We’ve been life testing heat pipe systems for over 40 years to ensure heat pipe longevity and reliability. Mix and match Boyd’s broad technology portfolio for an optimized thermal solution.

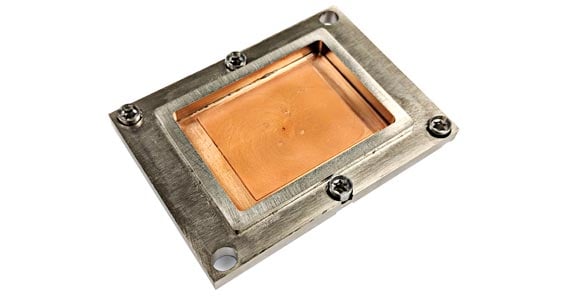

Vapor Chambers and Vapor Chamber Assemblies

Vapor chambers offer design flexibility and extreme heat spreading and are easily integrated into heat sinks for optimized performance. Vapor chambers leverage a variety of materials and working fluids, including Boyd’s ultra-thin copper-water and stainless steel vapor chambers for high density cooling in low profile mobile electronics and PEM cells.

Immersion Cooling

Improve heat transfer from the heat source to the liquid, with evaporators or boiler plates in lieu of heat sinks or liquid cold plates. Boiler plates provide additional surface area to capture device heat and bubble away heat. Boyd develops and manufactures boiler plates using techniques refined from decades of two phase cooling experience.

Thermosiphons

For additional cost savings, Boyd offers advanced engineering and streamlined manufacturing that enables one shot brazing. Boyd has also developed loop thermosiphon solutions that offer passive liquid cooling for more reliable high-power cooling.

Thermal Control Units

Pumped Two-Phase Cooling Systems

Have questions? We’re ready to help!