Adhesives

Adhesives form robust bonds and are easy to apply, making them ideal to seal or laminate applications in diverse industries.What are Adhesives?

Adhesives are substances formulated to stick materials together. They can create strong and enduring bonds or temporary attachments. Diverse adhesives unite different materials at specified strengths and for varying periods of time. These versatile solutions are crucial in various applications to permanently or temporarily bond different materials or components together. Common adhesives feature acrylic, silicone, rubber, urethane, or epoxy chemistry. New bio-based and bio-decomposable materials are emerging to contribute to sustainable product development. Various adhesive types cater to specific needs, offering flexibility based on materials and application requirements.

Adhesives Material Science at Boyd

Boyd’s 70 years of adhesive expertise has built a comprehensive understanding of adhesive material science, selection, and processing. We design solutions featuring a wide range of adhesive materials in diverse applications. This broad proficiency enables us to create intricate, multifunctional solutions that seamlessly integrate performance characteristics of diverse materials. Adhesives are integrated with foam, rubber, plastic, metal, and other materials to bond surfaces together, seal, cushion, absorb sound or vibration, and many other applications.

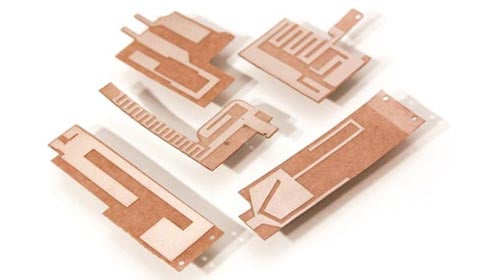

Leveraging our innovative rotary die-cut processes, material expertise, and controlled clean room environments, we excel in constructing advanced adhesive solutions that cater to demanding performance needs. Boyd maximizes adhesive material yield and utilization, which can be an important differentiator when working with advanced adhesives that are expensive materials in a product design. Advanced adhesive applications include bonding displays with optically clear adhesives into touch screens, safeguarding wounds with medical-grade adhesive bandages or dressings or adhering medical wearable devices to patients.

How an adhesive product will be applied in customer assembly processes should affect adhesive material choice, fabrication, and finished product presentation. Boyd’s adhesive expertise extends to how a finished product will be applied within customer applications, helping customers maximize assembly efficiency and accuracy for total cost management and faster speed to market.

Medical Grade Adhesives

Medical grade adhesives are commonly sterile and disposable tapes designed to provide secure yet gentle bonding to skin. These adhesives are used to treat wounds, attach medical wearable devices to patients, or can be embedded with pharmaceuticals as transdermal patches. Stick to skin adhesives are subject to rigorous standards for safety, biocompatibility, and effectiveness across diverse medical settings, skin types, and applications. Medical adhesives are also crucial for durable medical devices. They can be used to bond internal or external components in or to a medical device throughout the equipment’s lifespan. Stick to skin and durable medical device adhesives constantly evolve to meet the dynamic needs of medical professionals and ensure they consistently meet stringent performance, safety, and biocompatibility standards in the ever-evolving field of healthcare.

Adhesive Materials

| Material | Definition | Why to Use | Products & Industries |

|---|---|---|---|

| Acrylic | Acrylic adhesives are based on acrylic polymers and offer strong bonding capabilities and versatility to diverse substrates. Acrylic tapes can be single or double sided. | Acrylic adhesives provide durable bonds. They are resistant to weather, aging, and UV light. Acrylic adhesives are suitable for a wide range of applications and bond well to plastics, metals, and other substrates. Acrylic adhesives are one of the more commonly used solutions in most markets. | Sealing and protecting electronic components. Assembly of circuit boards. Medical wearable devices. Medical tapes. Medical dressings and securement. Automotive manufacturing. Assembly of interior and exterior components in automotives. Lighting assembly in automotives. |

| Biobased | Biobased adhesives are derived from renewable, natural resources such as plants, animals, microorganisms, or biomass. | Biobased adhesives offer several environmental, economic, and sustainability advantages. | Assembling automotive components. Producing medical tapes, dressings and bandages. Product labelling. |

| Epoxy | Epoxy adhesives or epoxy resin adhesives, belong to a class of structural adhesives known for their exceptional bonding strength, durability, and versatility. | Epoxy adhesives offer exceptional tensile and shear strength, adhere well to a range of materials, have excellent electrical insulation and high durability. Extreme bond strength and durability make epoxies great for long term applications. | Encapsulating electronic components. Bonding circuit boards. Sealing electrical connections. Bonding components in aircraft and automobiles. |

| Foam Adhesives | Foam adhesives or foam tapes feature either adhesive coated onto a foam or formulated within the foam structure. Foam adhesives and tapes can be single or double sided. | Foam adhesives and tapes are great for bonding materials with uneven or irregular surfaces, large gaps, and applications with flexibility, movement, or vibration. They exhibit good temperature resistance and are soft and compressible. Depending on the foam type and compression, they make great seals. | Bonding trim, emblems, and other components in automotive manufacturing. Cushioning in automotive interiors and electronic devices. Seals and gaskets in automotive, electronic, and industrial applications. |

| Rubber | Rubber adhesives are formulated to bond rubber and related elastomeric materials. | Rubber adhesives are formulated to adhere to rubber surfaces that are difficult for other adhesives to bond to. They maintain flexibility and can accommodate movement and deformation of rubber materials without losing bond strength. | Bonding rubber seals, gaskets, hoses, and components in vehicles. Bonding rubber components in electronic devices to insulate and seal. Assembling medical devices with rubber components. |

| Silicone | Silicone adhesives are based on silicone polymers. | Silicone adhesives are optimized to adhere to silicone surfaces. They are highly stable, temperature resistant, and chemical resistant with excellent electrical insulation properties. They are resistant to yellowing over time. | Bonding. encapsulating and sealing high temperature components. Bonding and sealing medical devices. |

| Urethane | Urethane adhesives or polyurethane adhesives, belong to a class of structural adhesives that are based on polyurethane polymers. | Urethane adhesives offer strong bonding capabilities, flexibility, and versatility in adhering to a wide range of materials. | Bonding interior and exterior components, including panels, trim, and weatherstripping in automotives. |

Diverse Approaches Tailored for Specific Applications

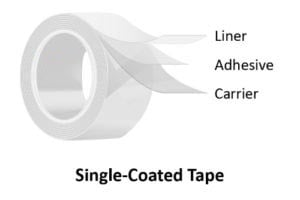

Adhesive tapes consist of three essential components: the adhesive, the carrier material (or backing material), and the release liner. Precision converting commonly employs adhesive transfer tapes, single-coated (single-sided) tape, and double-coated (double-sided) tape in solutions across diverse industries.

Single-Sided Adhesive Tapes

Single-sided adhesive tape consists of a carrier or backing material coated with adhesive on one side. These tapes serve as effective solutions to bond, seal, splice, protect, mask, or as labels across diverse industries. The carrier helps single sided tapes maintain structural integrity.

Double-Sided Adhesive Tapes

Double-sided tape has adhesive on both sides of a carrier material. These tapes may feature the same or different adhesives on each side. Differential adhesive tape features different adhesives on each side to bond dissimilar materials. Double sided tapes are widely used to bond, mount, splice, or package applications across various industries and are increasingly replacing mechanical fasteners. The carrier helps double sided tapes maintain structural integrity.

Adhesive Transfer Tapes

Adhesive transfer tapes, or unsupported or free film tapes, feature pressure-sensitive adhesives pre-applied to a release liner. These tapes do not have a carrier and offer flexibility, quick adhesion, and strong performance, including good adhesive wet out, shear strength, and holding power at elevated temperatures.

Overcoming our Customers’ Challenges

Boyd has innovated adhesive selection and converting for more than 70 years, establishing exceptional expertise in the design, handling, and processing of adhesive materials. We are dedicated to utilizing cutting-edge technologies customized to the distinctive needs of each application. Our focus is on addressing and overcoming customer challenges, consistently delivering innovative solutions and adhering to the highest standards of quality and performance.

Optimal Adhesive for Your Application

Drawing on over 70 years of experience, we collaborate with our strategic supply partners that are recognized as global leaders in tape and adhesive formulations. Our expertise extends to understanding the science behind the application of these innovative formulations to your custom-designed applications. We actively guide you in selecting the optimal formulation based on your performance requirements and intended usage environments. By implementing industrial design for manufacturing methodologies, we ensure that your components are manufacturable within your design tolerances and delivered in a custom-configured format optimized for automated or manual assembly into your application. Our specialization lies in translating adhesive science into tangible components that are optimized for cost and performance throughout your entire value chain.

Have questions? We’re ready to help!