Commercial Aerospace and Space

Commercial air travel, scientific space exploration vehicles, and global communications satellites operate in the most dynamic conditions known to mankind. These applications require fully optimized systems that need little to no maintenance and are lightweight to ensure maximum fuel efficiency and payload capacity. Boyd’s engineered materials technologies are deployed to seal, shield, and protect passengers, as well as sensitive instruments which are critical to safe and effective operation.

Innovate to Differentiate Performance

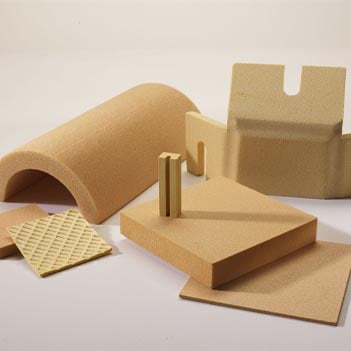

SOLIMIDE® Foam Sustainable Insulation Improves Safety while Lightweighting

SOLIMIDE® is an environmentally friendly, non-toxic, low density, light weight, polyimide foam designed as a high performance thermal and acoustic insulator with a uniquely wide continuous temperature range from below -325°F(-200°C) up to +572°F (+300° C). When exposed to flame, SOLIMIDE® chars rather than burns, creating a burn barrier, will not propagate flame, and emits very little smoke and no toxic fumes. It is neither hydrophobic nor hydrophilic so it doesn’t wick liquid and will float atop resting water. SOLIMIDE® foam is basically inert and doesn’t outgas, is resistant to most petroleum chemicals, doesn’t support microbial growth, is non-toxic, and doesn’t significantly change size going from extreme cold to extreme heat. When used to insulate aircraft fuselage, aerostructures, the cockpit, cabin, and cargo bay, SOLIMIDE® improves passenger and crew safety while lightweighting the aircraft to improve fuel efficiency and progress to sustainability goals.

Reduce Weight to Improve Fuel Efficiency for More Sustainable Aircraft

Allocate weight savings to greater onboard fuel storage for improved range or translate weight savings to better fuel efficiency and operator savings. Boyd’s lightweight, low mass, high performance liquid cooling and insulation systems feature innovative materials with high inherent strength at a reduced weight, fabricated for reliable long-term performance.

Create Safer, Quieter, More Comfortable Aircraft

Engine noise and temperature extremes are two primary factors that impact passenger comfort. Self-supported, ultra-lightweight thermal and acoustic insulation, SOLIMIDE® Foam, acts as a self-extinguishing flame blocker, exceeds FAR 25.856 flammability requirements, and emits very little smoke if exposed to flame. Meaning you can safely minimize engine noise and control extreme temperature exposure to the cabin without adding excessive weight, fire, or toxic smoke risk.

Enhance Comfort and Safety with Human Machine Interface Solutions

Markings, Printed Circuits Electromechanical Assemblies, and Molded Solutions

Between Boyd’s plastic injection molding, display integration, assembly, printed electronic circuitry, and specialty printing, Boyd fulfills the capabilities of multiple suppliers. From warning and safety labels to seat markers, Boyd has the expertise and capabilities to produce a broad spectrum of interior and exterior graphics for the aerospace industry. Boyd offers full-service plastics capabilities including injection molding, decoration, and assembly with our dedicated team. Leverage our breadth of experience designing sub-assemblies and complete functional devices to bring customers the best front panel solution, meeting both functional and aesthetic requirements at a competitive price.Lower Total Cost of Ownership

Minimize or remove waste in manufacturing with optimized raw material utilization and during aircraft operation with integrated solutions that seal, and protect, designed for highest efficiency fuel and energy use. Reliable components optimize performance and prevent unexpected fleet downtime and fees. Products are designed to optimize service processes and speed during planned maintenance and repair operations for minimized downtime and MRO costs. Boyd’s widely diverse, overlapping technology portfolio enables many competing technologies to co-exist and Boyd to recommend optimal solutions for each application. All of these value drivers give you the best total value solution for your unique needs

Aerospace-Grade Quality Manufacturing

Boyd’s AS9100C certified aerospace manufacturing facilities feature quality management systems with the highest level of aerospace quality assurance throughout design, prototyping and mass production. Boyd aerospace products go through stringent environmental testing to qualify each design in application with rigidly controlled manufacturing processes that assure product consistency, meaning all manufactured components match the character of qualified designs. Highly reliable components come from replicated regional design and production operations. Many AS9100C certified sites are available across North America and Europe for redundant manufacturing processes and robust contingency planning.

SOLIMIDE® Foam vs. Other Open Cell Foam: Fire Resistance Test

(View transcript)

What Goes Into Making Advanced Display Solutions?

(View transcript)

Advance Aircraft Electrification with Liquid and Air Cooled Systems and Chassis

High reliability, lightweight, low mass, low profile cooling systems enable advancements in aircraft electronics without adding weight or bulk to aircraft designs. Liquid cooled electronic chassis efficiently draw heat away from critical electronics through the chassis enclosure, enabling greater power and compute density in the same space without adding mass. Vacuum brazed liquid cold plates efficiently transfer heat from electronic systems generating high heat loads to existing coolant loops with high reliability. Vacuum brazed air-cooled heat sinks draw heat out of medium and low powered electronics with high reliability. Heat pipe assemblies move or spread heat from a heat source to a more remote area where heat can safely dissipate with greater access to air cooling.

Commercial Satellites

Satellites are an integral part of our communication and navigation infrastructure, enabling consumers, businesses, and service providers accurate information worldwide. To enable reliable operation, satellites require maintenance-free thermal management solutions to maintain optimal operating temperatures for onboard electronics. Boyd’s axially grooved ammonia-aluminum heat pipes, encapsulated graphite thermal straps, radiator panels, and heat spreaders, and long-distance loop heat pipes are passive components that reliably move and radiate heat to ensure long satellite system lifetimes.

Rugged, Lightweight Solutions

Lightweight and rugged avionics, motor and electronics cooling solutions in electric vertical take-off and landing aircraft (eVTOL), electronic heat transport to stowed radiator panels during satellite launch.

Enable Radical Changes in Aircraft Engine Design with High Performance Heat Exchangers

Aluminum and high temperature plate fin heat exchangers are a compact cooling option for applications with tight volume or weight requirements. The construction enables heat exchangers to withstand high pressures and demanding aerospace environments for aircraft engine innovation.

Related Products & Resources

Have questions? We’re ready to help!