Electronic Displays, Touch Screens, and Human Machine Interfaces

What are Display Modules and Why Does it Matter?

Display modules are electronic components that include LED (Light Emitting Diodes), OLED (Organic LEDs), LCD (Liquid Crystal Display) modules, and emerging technologies designed to make displays lighter, thinner, brighter, and more energy efficient.

What is a Touch Screen Module?

When coupled with touch sensing functionality, displays double as touch screen Human-Machine Interfaces allowing users to interact with a device. Displays and touch screen modules are so versatile that they have become ubiquitous in today’s connected world. Users expect new products to leverage touch screens and displays as an interface, making them an essential design component across most applications. Application requirements for each touch screen can vary significantly and quickly become one of the most complex components of your product that differentiates the unique user experience.

What are Display Enhancement Films?

Improve Efficiency

Better light utilization enhances energy efficiency

Increase Brightness

Specialized film improve display contrast, clarity, and vivacity without increasing power demand

Extend Battery Life

Better light utilization and enhanced energy efficiency means displays are less of a battery drain

Why Boyd for Display and HMI Solutions?

We innovate how optical materials converge to solve OEM challenges, streamline access to material innovation, and optimize how display integrators assimilate optical components in a display stack.

We help you select optimal materials that balance achieving your desired display performance while optimizing cost and assembly complexity.

Our material science breadth gives you streamlined access to the world’s most advanced optical material innovation and all key suppliers.

We give you unlimited flexibility in material combinations to enhance performance and enrich value.

Our Design for Manufacturing (DFM) assures your display components easily assimilate in your display subassemblies.

Our ability to source and manufacture product in all key geographies gives you regional flexibility.

We have experience supporting and managing all major display integrators with long term, existing relationships.

In-Mold Decoration (IMD ) and In-Mold Labeling (IML) Solutions

(View transcript)

Human Machine Interface Solutions for the Automotive Industry

(View transcript)

What is Inside Advanced Display and Touchscreen Solutions?

(View transcript)

Advanced Display and Touch Screen Benefits:

Enhanced User Experience: Intuitive user interface easily displays dynamic information and menus for a broad range of functionality.

Differentiated Brand Experience: Well-designed displays offer a more immersive experience with rich vivacity, sharp contrast, and reliable performance in diverse settings with various light levels and sources.

Distinguished Sustainability: Smart designs optimize display battery consumption by using low profile, lightweight advanced filmic materials to concentrate produced light toward the viewer, maximizing the visual experience and reducing overall display module weight.

Display Challenges:

Design Knowledge: With displays proliferating across most applications, diverse OEMs may not have display design expertise, display material experience, or know-how to best integrate displays into their applications

Manufacturing Complexity: Challenge to achieve high yield rates with difficult to handle adhesive or film materials and high optical clarity requirements

Smaller, Thinner Form Factors: Product designers need displays in smaller, thinner dimensions with little to no bezel designs to meet consumer demands. Tighter assemblies also mean displays are closer to heat generating components and require protection for reliability and long lifetimes

Weight Critical: Many displays are either carried by consumers or mounted on mobile assemblies where weight impacts efficiency or transportation range.

The Boyd Difference for Advanced Display and Touchscreen Solutions

We’ve innovated our advanced material fabrication processes over the last 20 years to consistently deliver high quality optical display components with exceptional tolerance control at high volume mass production to help the most sophisticated mobile electronics brands in the world optimize display performance and component cost. We continue to tirelessly push advanced display component process innovation to help our customers continue to differentiate and leverage our heritage to help brands new to advanced displays navigate this complex technology.

Boyd’s Advanced Display Heritage

- 15+ years of field-proven performance in display applications

- 1 billion + display components shipped

- 5 million + Micro OLED component installations

- Trusted advisor to OEMs and Tier 1 partners

- Pioneer in critical display solutions for electronics and electric vehicle applications

- End-to-end in-house validation

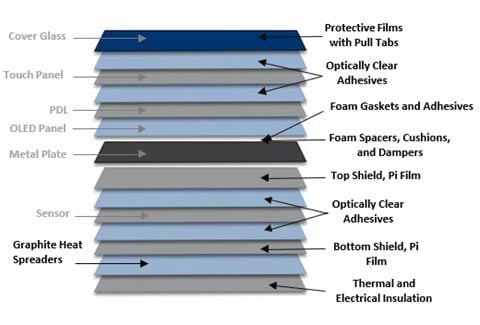

Segmented Frame Technology

Boyd’s proprietary Segmented Frame Technology leverages our deep, innovative processing knowledge with proprietary designed advanced rotary converting equipment to integrate multiple material layers at maximum raw material utilization. We’re able to combine multiple display bill of material (BOM) components in one-pass manufacturing for one easy-to-assemble final product deliverable that helps our customers accelerate assembly processes as they integrate display modules into their applications.

- Tolerance control down to +/-0.05mm

- Integrate multiple materials and display components into one easy-to-assemble final product

- Improve assembly cycle time

- Maximize raw material use

- Minimize material yield loss

- Integrate display mount adhesives, bezel bonds, cushions, spacers, insulation, thermal management, shielding performance, and optical functionality into one component

Material Science and Handling Expertise

Optical materials are designed to enhance display performance and efficiency. To do this effectively, they must be visually perfect and free of foreign debris and contaminants. These specialty materials require special protocols to assure zero defects impacting how optical and display materials are transported, packaged, stored, handled, and processed.

Boyd maintains a variety of clean room environments in all key geographies with processes and protocols to handle and fabricate display materials with increasing levels of cleanliness requirements:

- Contaminant-free material storage and handling protocols

- Cleanroom raw material slitting and preparation processes

- Cleanroom advanced rotary converting manufacturing lines

- Cleanroom flat bed converting manufacturing lines

- Cleanroom cosmetic inspection

- Class 100 clean rooms

- Class 1000 (Class 1K) clean rooms

- Class 10000 (Class 10K) clean rooms

- Class 100000 (Class 100K) clean rooms

- UV sensitive clean room manufacturing

- Temperature sensitive material handling processes

Cleanroom environments include ongoing monitoring to assure optical materials and display components are contaminant-free and on-specification:

- Filter installation leak testing

- Airborne particle count testing

- Airflow velocity testing

- Temperature testing

- Relative humidity testing

- Light intensity level testing

- Sound pressure level testing

- Room pressurization testing

Supply Chain

The display module value chain is very complex with many players. Boyd helps to simplify this for you, delivering differentiated performance at optimal total cost.

Raw material suppliers innovate material formulations and enhance material performance. They produce large format rolls and sheets of raw display materials. Boyd has strategic supply relationships, dating 50+ years, with the leading raw material suppliers like 3M, tesa, and Nitto. We continue to actively search for new entrants with innovative materials that can help our customers differentiate experience.

Many OEMs rely on display integrators to design and deliver custom display modules that meet their needs. These integrators are experts in display module design and assembly, delivering on-specification subassemblies to OEMs for integration into their final product. Boyd has 15+ year relationships with the world’s leading display integrators. We continue to establish new strategic relationships with new market entrants as our customers evolve their preferred display integrator partners.

Leverage Boyd’s 15+ years of display expertise to enhance your product.

Key Display Terms to Know

| Term | Definition |

|---|---|

| Battery Adhesives | Tapes that secure batteries near a display stack with high temperature-resistant adhesives. Increases product safety and extends battery life. |

| Regulatory Labels | UL compliant regulatory labels assure high brand compliance, safety warnings, and traceability. |

| Camera Gasket | Combined adhesive and film or foam that protects camera modules from water, vibration, and contaminants. Extends lifetime and improves performance. |

| Capacitive Touch Module | Tactile interface surface that enables users to interact with a device via touch. Has been replacing traditional membrane switches, elastomers, and full travel keyboards as the primary input method on many product designs. |

| Conductive Backlight Housing | Mechanical and thermally conductive structure that simultaneously supports the backlight unit and conducts heat away from the display to the ambient environment. Controlled backlight operating temperature maximizes color vivacity and display lifetime. |

| Diffuser Film | Specialized film that evenly distributes light across the screen. Optimizes full display visibility for better screen clarity, vivacity, and color trueness at a wider viewing angle. |

| Display Integration | Minimize engineering, design, and supply chain complexity with fully integrated subassemblies that include all display components, optical films, adhesives, and gaskets with a display housing and all connectors for streamlined assembly into your devices. |

| Brightness Enhancement Film | Specialized film that intensifies brightness, improves the user experience and display energy efficiency. |

| EMI Shielding | Shielding layer to reduce electronic malfunction susceptibility by blocking unwanted external electromagnetic waves to improve device and signal reliability. Eliminates internal display component cross talk. |

| Foam Adhesives | Prevent cracked or separated screens with strong display adhesion to the device, cushioned to absorb shock and vibration. |

| Front Frame Gaskets and Seals | Adhesive (foam) gaskets that ruggedize the joint between displays and front glass panels. Cushions vibration and shock to extend life and improve customer satisfaction. |

| (Graphite) Heat Spreaders | Thin, lightweight, thermally conductive material that spreads heat away from localized hot spots from high performance components. Maintains safe touch temperatures and prevents overheating. |

| LCD | Liquid Crystal Display |

| Lightguide Panel | Panel or film that concentrates and amplifies light from the backlight to the viewer. Improves display richness, sharpness, and efficiency. |

| LED | Light Emitting Diode |

| OLED | Organic Light Emitting Diode |

| Optically Clear Adhesives (OCAs) | Optically clear adhesive that mechanically joins surfaces with a matching refractive index to reduce light loss between substrates and give the appearance of being optically clear or invisible. Maximizes display clarity. |

| Protective Film | Films intended to prevent screen scratches or cracking during manufacturing, logistics, assembly, temporary consumer use, or durable long term protection. |

| Reflector Films | A display enhancement film that reflect light through the display, concentrating all generated display module light toward the viewer. More light reaching the user maximizes energy efficiency, display vivacity, and color trueness. In addition, by reflecting light back to the user, it minimizes light heating up and degrading components behind the display. |

| Segmented Frame Display Bonding Gasket | Boyd-developed proprietary high volume manufacturing processes to cut four pieces of a display frame separately and assemble into one deliverable with zero gap joint tolerances for waterproofing and dimensional control. Passes IP67 and push-out testing. Enhanced sealing performance with best raw material utilization. |

| Speaker Mesh | Acoustically transparent synthetic or woven metal mesh filters enable high quality audio while sealing out water and contaminants. Seal out water and particulates from devices with acoustically transparent filters for high quality speakers and microphones. |

| Polarizer Film | A display enhancement film that boosts performance by transmitting one polarization and the other reflected light is recycled in the backlight. |

| Security Films and Antiglare Films | Anti-Glare & Security Films are display enhancement films that reduce the viewable angle of screens with specialized microlouvers that block light exiting from the sides of a screen or display, but around 60° of light in the middle viewing angle can freely reach viewers. Reducing glare and reflections are essential for displays used in varying lighting environment like consumer or emobility |

Closing

Boyd has shipped more than 1 billion display components over 15+ years. We’ve helped the leading mobile electronics brands differentiate their products with high performance displays that enrich the immersive consumer experience, reduce weight and battery drain while pushing the boundaries in creative manufacturing that optimizes cost.

Have questions? We’re ready to help!