Conduction Cooling

Spread high density heat loads with graphite heat spreaders, encapsulated graphite chassis and enclosures, and thermal interface material.

Reliable and Passive Conduction Cooling Solutions

Passive conduction cooling is an essential tool for reliable heat transfer and one of Boyd’s areas of expertise for over 50 years. Thermal interface materials (TIMs) are essential for improving air- or liquid- cooled solutions, high conductivity materials like encapsulated graphite heat spreaders help manage high heat densities, and thermally conductive chassis and enclosures, flexible thermal straps, and rugged thermal busses provide reliable heat transport solutions.

Have a Question?

How Does Conduction Cooling Work?

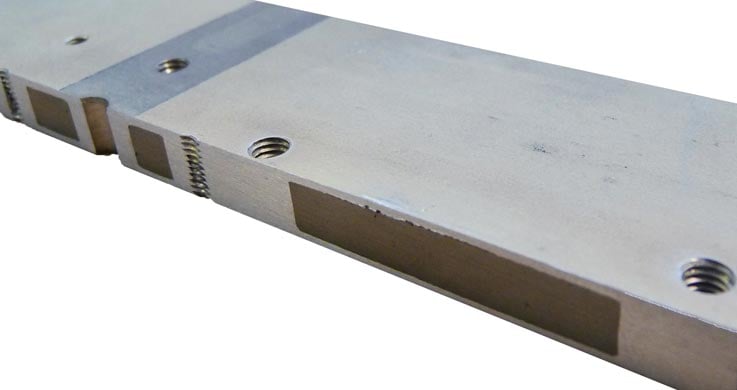

Conduction cooling solutions rely on direct contact with materials with high thermal conductivity to effectively transfer heat. Conduction solutions can be simple like thermal interface materials, often a film or silicone pad embedded with high conductivity filler, or they can be more complex solutions like a lightweight aluminum chassis with an encapsulated graphite core.

Aviation

Passively cool avionics and other sensitive electronics in a rugged, reliable format that withstands harsh operational conditions.

Space

Lightweight, passive, conduction cooling systems withstand the rigors of launch, landing, and operation, enabling reliable performance for satellites and rovers.

Boyd’s Material Science Expertise for Conduction Solutions

In addition to a broad portfolio of traditional conduction solutions, Boyd is a leader in creating advanced conduction solutions utilizing encapsulated graphite to combine lightweight, highly thermally conductive graphite into either machinable or flexible formats in our k-Core® product line.

Learn about Boyd’s solutions in the sections below:

Thermal Interface Materials

Thermal Interface Materials (TIMs) play a critical role in effective thermal management systems by facilitating heat transfer between solid surfaces.

Thermal Straps and Busses

Passive thermal management technologies used to conduct heat from sensitive components to another surface.

Heat Spreaders

Heat spreaders can be integrated into complex assemblies or geometries for high performance chassis or enclosures where internal volume is at a premium.

Have questions? We’re ready to help!