Immersion Cooling: Next Gen Performance

Immersion cooling enables high heat transfer from high flux heat sources like CPUs and GPUs with passive two-phase cooling, enabling greater reliability and longer product lifetimes.

Increased Processing Power

Enable higher electronic density compared to other cooling technologies.

Generative AI and Hyperscale Computing

Cool power-hungry chips with rapid, high capacity cooling

Reduced System Complexity

Simplify complex systems by eliminating fans, air ducting, baffles, pumps, and manifolds.

Improved Noise Safety

Eliminate active components like fans and blowers with passive immersion cooling.

Next Generation Liquid Cooling for Extremely High-Power Applications

Immersion cooling is a specialized system that leverages the high heat capacity and rapid heat transport of two-phase cooling in system designed to dissipate massive amounts of heat. This system utilizes an innovative approach specifically designed for cooling highest heat load applications such as generative AI systems, hyperscale computing, and supercomputers.

Mounting boiler plates to high performance chips quickly and efficiently removes heat from sensitive components when placed in an immersion cooling system. Customers can boost performance for chips with high heat dissipation where standard air cooled, or liquid cooled solutions cannot meet application requirements.

Have a Question?

How Does Immersion Cooling Work?

Liquid immersion cooling systems include a boiler plate attached to a heat source that is immersed in a dielectric fluid. The immersion liquid boils when it contacts the plate, absorbing heat from the plate and the connected heat source. The bubbles that boil up in the fluid bring the heat to the surface and reject the heat from the system where it condenses at a heat exchanger or coil.

Why Use Immersion Cooling?

Immersion cooling boosts cooling capacity to enable increased processing power and electronic density compared to other cooling technologies. Two phase immersion eliminates complex air flow management and tube routing required in air or direct liquid systems. This simplification reduces hardware requirements, shortens development cycles, and streamlines assembly. All components have access to cool ambient liquid without any preheat from upstream components for immediate cooling and balanced temperatures. Leveraging passive heat transfer within the rack or tank eliminates local pumps and fans requirements which provides quieter environments with increased noise safety. Immersion systems reduce moving parts and limit non-IT power consumption from fans and offer a highly reliable and efficient cooling solution.

Why Use Boyd’s Immersion Cooling Solutions?

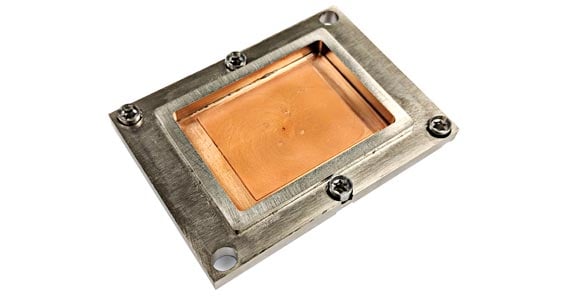

Boyd’s Immersion Cooling Boiler Plates are extremely high performance differentiated with a boiling enhancement surface (BEC) optimized with high wicking and boiling capacity to ensure consistent fluid flow to the surface.

Our engineering team is well-equipped to meet custom design, performance, and mounting requirements for specific applications. Boyd engineers are trained to choose the best BEC, base, and frame materials, identify the right fluid, and utilize a BEC configuration to optimize your system.

Ready Designs for Common High Performance Semiconductors

In Boyd’s standard immersion cooling boiler plates, the BEC is assembled within an aluminum mounting frame which provides high mounting forces to enable thin thermal interface material bond lines while still maintaining the structural integrity of the board. The BEC is assembled within an aluminum mounting frame which provides high mounting forces to enable thin thermal interface material bond lines and maintain the structural integrity of the board. Our immersion boiler plates come preassembled with Intel® Xeon® or AMD SP3 compatible hardware and pre-applied with thermal grease for fast installation. For more specialized applications, contact our engineering team to develop the best-fit solution for your project.

Have questions? We’re ready to help!