Battery charge range historically challenged consumer adoption of electric vehicles (EVs). But innovative EV designers have found creative ways to make drastic battery charge range improvements and the electric vehicle industry continues to grow at a rapid pace with EV adoption significantly increasing. Over the last ten years, some estimates suggest that average electric vehicle battery range has increased more than fourfold. This increase in power brings key thermal challenges. Increasing EV adoption elevates the need for more ruggedized EV battery designs to extend lifetime performance and control or reduce warranty claims.

Boyd’s innovative team of experts and design leaders are at the forefront of solving these challenges. We’re helping pioneers in this space accelerate innovation. Our engineers develop integrated thermal and engineered material solutions that enable smaller, ruggedized, lighter, more efficient, and more reliable batteries with faster charge cycles for greater electric vehicle range, safety, and reliability.

Thermal Runaway?

Lithium-Ion thermal runaway occurs when heat generated by a battery exceeds the amount of heat being dissipated. Unmanaged heat can cause an uncontrolled chain reaction to surrounding batteries and li-ion battery cells. When li-ion thermal runaway isn’t handled properly, batteries overheat produce smoke, and combust.

Multiple factors cause thermal runaway, some include internal and external short circuits, overcharging, high ambient temperatures, rapid cycling, and battery age. Effective thermal management is vital not only to an electric vehicle battery, but also to vehicle occupant safety.

How to Prevent Li-ion Thermal Runaway? Battery Thermal Runaway

Need to Be Ruggedized?

Harsh environmental conditions are an everyday reality for electric vehicles. EV batteries and components need to be protected during operation to extend performance lifetime and reduce warranty claims. Ruggedized EV batteries can withstand and perform better against collision impact, ongoing shock and vibration, extreme road conditions, and extreme weather conditions.

How to Protect EV Batteries?

Battery Cell and Battery Module

Improve battery performance, safety, and reliability with EMI and RFI shielding. EMI Shielding prevents both the input and output of radiofrequency interference (RFI), electrostatic interference (ESD), or electromagnetic interference (EMI), all of which are highly prevalent in complex electrical systems in electric vehicles. EV battery EMI shields protect battery performance and prevent electronic malfunction in critical safety systems. Boyd’s conductive foams, elastomers, adhesives, foils, and more are designed to mitigate this interference and shield unwanted signals, improving reliability and efficiency in EV batteries.

Wrap EV Battery Cells with Electrical Insulation

Dielectric Adhesives on Busbars

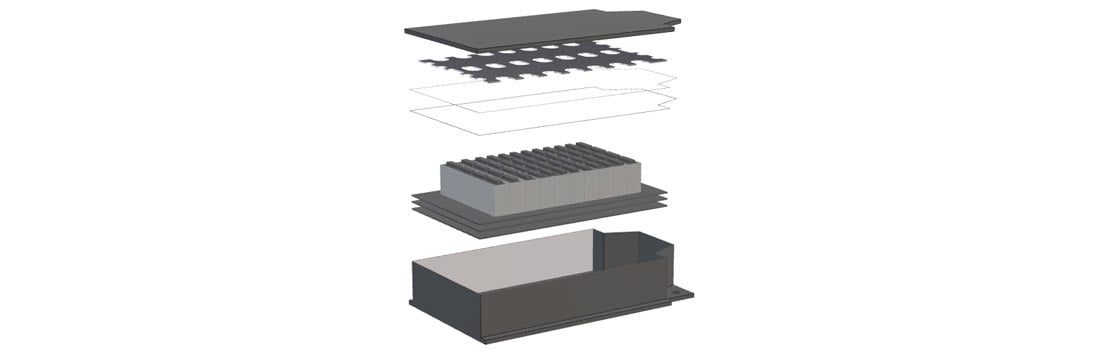

EV battery cooling solutions must meet heat challenges and overall design requirements but cannot add weight or bulk to preserve EV battery charge range. Lightweight battery liquid cold plates provide Robust Structural Support (RSS) and maximize battery heat removal for today’s highest performing electric vehicle battery modules and packs. Low-profile cooling plates efficiently cool batteries and create extra design space in the battery compartment, making room for larger, more powerful batteries.

Boyd’s custom EV battery cold plates optimize internal geometry to maximize turbulent flow and external geometry with skylines and pedestals customized to your battery design to maximize heat source contact and thermal dissipation. Boyd’s battery liquid cooling plates have one hundred percent in-line thermal testing and decades of trusted market performance to assure reliability.

Improve heat transfer between the battery cold plate and battery module by minimizing thermal resistance between these two surfaces. Thermal Interface Materials (TIMs) minimize heat flow resistance between surfaces, more efficiently moving heat away from sensitive EV batteries into the liquid cooling system through the battery cooling plate.

Boyd’s thermally conductive tapes, gap fillers, thermal pads, films, phase change materials, and thermal grease maximize battery liquid cooling system performance by more efficiently moving heat from the battery to the liquid cold plate.

Whether it’s protecting and cooling EV batteries, creating smart displays and telematics, optimizing EV charging, elevating EV brand identity, and more, Boyd helps eMobility designers and market leaders accelerate innovation. For more information about Boyd’s EV battery solutions, watch our video below. For specific questions about your application, reach out to our experts.