EV/HEV Charging and Batteries: Powering eMobility Solutions

EV Charging Solutions: Seal, Protect, and Control Energy Flow in an Electric Vehicle

The success of any electric or hybrid/electric vehicle (EV/HEV) relies on how well it stores energy and how quickly it recharges. Once the effective vehicle range of a single charge compares with a quick fill up at the gas pump, consumers are more likely to make the transition to an electric vehicle. OEMs are at the forefront of pioneering innovations in EV charging solutions, aiming to enhance battery capacity, efficiency, and lifespan, while also minimizing charging times making EVs and HEVs more attractive to consumers.

Any industry-changing innovation is not without its challenges; vehicles are limited on space, weight, and power, and must meet demanding cost and reliability requirements (SWAP-CR). Vehicles are subject to harsh environmental constraints, which can pose difficult environmental sealing and protection requirements for large electronic systems and batteries. Additional electronic consumption poses its own thermal management challenges as power conversion and electronic controllers that manage the system produce waste heat that, if left unchecked, can damage the system.

Top Three Causes of Thermal Runaway and How to Prevent Them

(View transcript)

How to Cool and Protect EV Batteries Against Collision and Thermal Runaway

(View transcript)

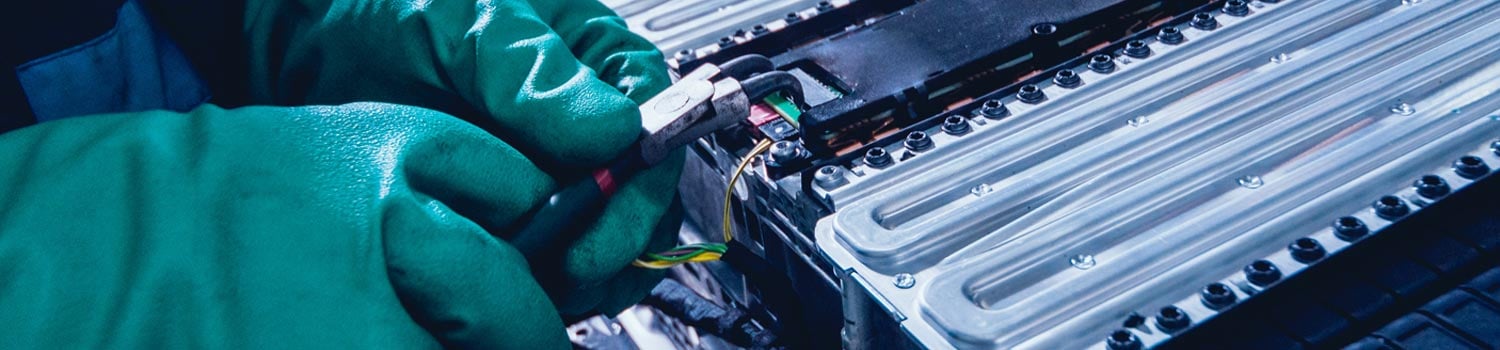

Long-standing Expertise

Leverage Boyd’s expertise in EV charging solutions with our extensive experience in Engineered Materials and Thermal Management Solutions. Boyd is an ideal partner in developing and manufacturing products that help seal, protect, and control energy flow in an electric vehicle. Our precision converting capabilities enable us to develop robust, cost-effective and reliable seals to protect power converters & inverters, electronic control units (ECUs), charging stations, and battery compartments from particle and fluid ingress or contamination and water damage. Enclosing these high-power density components for protection creates a secondary issue of trapping excessive heat in the enclosures, which can damage expensive electronics. This is where Boyd helps you design and fabricate an effective battery cooling system that includes thermal management solutions for the charging cables and power conversion components. From high volume brazed liquid cold plates and vapor chambers to thermal interface material, Boyd can optimize the thermal performance of your design.

Boyd maintains IATF 16949 certified manufacturing operations across three continents to assure our eMobility components exceed the rigorous demands for automotive quality management systems with adept regional support. Boyd’s customer focus and relationship management culture are aligned with IATF 16949 processes and quality systems. By optimizing processes, organization, and efficiency, we reduce costs, increase yield rates with effective management and assembly processes, all while providing our customers the highest quality products.

Batteries and Battery Packs

Maximize electric vehicle efficiency with Boyd’s comprehensive EV charging solutions. The effectiveness of an electric vehicle hinges on its battery, a key factor determining the effective range the vehicle has on a single charge. Batteries store DC power in between charges for the rest of the vehicle’s electronic systems to consume during operation. An EV’s battery pack is typically constructed from a series of battery cells consisting of lithium-ion (Li-ion or Li-ion cells), either in the form of small cylinders or flat rectangular pouches. Alternative technologies like fuel cells are also options in power storage for electric and hybrid vehicles. The battery is relied on to power the entire vehicle and has a significant weight and space allocation within, which OEMs endeavor to optimize and improve with each design iteration. Smaller and lighter weight batteries enable designers to incorporate higher powered or more densely packed battery cells for greater range. Partnering with Boyd’s design and engineering team enables you to develop optimized solutions that protect your battery from environmental conditions and improve power storage performance and efficiency. We create integrated solutions using highly engineered materials like SOLIMIDE ® Foams, Heat Shields, and battery gaskets to make your battery enclosures safe and reliable. We design thermal management solutions to efficiently manage battery pack temperature regardless of external environmental temperatures or generated waste heat. Boyd’s integrated solutions enable you to better protect passengers and improve the overall safety of your electric vehicle.

Charging Stations & Electric Vehicle Service Equipment

Charging stations and Electric Vehicle Service Equipment (EVSEs) play a crucial role in transforming EV charging solutions by facilitating power transfer from the grid to an electric vehicle. They constitute the backbone of the charging infrastructure, driving the evolution and accessibility of electric vehicle charging technologies.

Chargers come in different levels that reflect the amount of power consumption and recharge speed:

Level 1: Typical household chargers that charge a battery overnight

Level 2: Some household chargers that take a few hours to reach full battery charge

Level 3: Superchargers

Higher level chargers require more power for shorter charge times, with a major milestone of providing 100 km driving range in just 10-12 minutes. The eMobility industry is shifting to fast charging, which requires higher voltage, to compete with traditional internal combustion engines (ICEs) refueling time cycles.

Some chargers have the capability to convert AC power from the grid into a DC current and voltage that will safely charge the electric vehicle battery. These types of chargers use an electrical inverter, a series of electrical switches that rapidly alternate to transform the AC current to a DC current. These inverters may also include step down converters or buck converters to bring high DC voltages to the preferred battery voltage. These electronic switches fire quickly to enable fast charging, a process that generates large amounts of heat. This waste heat poses risk to safe charger operation and reliability, making effective thermal management and cooling solutions a requirement to ensure components work effectively and reliably over the lifetime of the charger.

Level 3 charger cables generate excessive heat as a function of dimensional space. The large current is passed through smaller diameter cables that are required to accommodate weight and consumer lifting limitations, generating excess heat. Charging stations implement cable cooling to manage touch temperatures, control system temperatures to prevent long term systemic damage, and help protect the user.

Most of these chargers are installed in an outdoor environment and subject to external weather conditions. High power electronics within charger systems must be protected from rain, UV, wind contaminant, and other damages making charger enclosure systems, seals, and protection solutions critical to ensure longer and reliable product lifetimes.

On Board Charger

The On Board Charger (OBC) of an electric or hybrid vehicle is what converts AC power from the grid provided by the charging station into DC power that charges the battery. Batteries store energy as DC, so the more power that an OBC unit can handle and convert efficiently, the faster the battery can safely charge. The On Board Charger utilizes a series of semiconductor devices to convert AC current into DC. These semiconductor devices switch rapidly and produce large amounts of waste heat in the process. On Board Chargers might include a step down converter, buck converter or 3-phase Input Power Factor Correction (PFC) components in addition to the main inverter to decrease high DC voltages to lower battery voltages for safer storage. Semiconductors like IGBTs, MOSFETs, diodes, and automotive microcontrollers in the On Board Charger generate large amounts of heat during rapid charging processes. Effective thermal management and cooling solutions are required to ensure these components work efficiently, safely, and reliably over the lifetime of the charger.Boyd On Board EV Charging Solutions

Boyd’s EV charging solutions expertise covers all aspects of the sealing, protection, insulation, and thermal management requirements needed for an on-board charger, and typically in an efficient integrated solution. Our high-performance gaskets and seals used within thermally optimized air cooled or liquid cooled enclosures make us an ideal partner in developing effective EV charging solutions that meet your performance requirements. We integrate many functions into a single assembly reducing your overall costs by simplifying your supply chain, minimizing assembly time, and fabricating reliable solutions that reduce maintenance and warranty costs.

Have questions? We’re ready to help!