EV Battery Module Types

EV battery module types include pouch cells, cylindrical cells, and prismatic cells, each with distinct features to fit different vehicle designs, performance criteria, and cost considerations.

Pouch Cells

Pouch cells are flat, rectangular batteries enclosed in flexible, pouch-like packaging, engineered for seamless integration into irregular or confined spaces within a vehicle’s design. Their uniform distribution throughout the vehicle effectively balances weight and enhances stability, making them an ideal choice for custom designed EVs.

Cylindrical Cells

Cylindrical cells involve stacking then rolling battery materials into a cylinder-shaped container, resembling traditional AA batteries. Their high energy density and cylindrical design enable efficient cooling, making them an excellent choice to power long-range electric vehicles (EVs).

Prismatic Cells

Prismatic cell batteries are a variant of rechargeable lithium-ion batteries, distinguished by their flat, rectangular or square shape. These cells can be designed with integrated thermal management systems and protective layers within the module, effectively mitigating risks such as overheating and short-circuiting. Prismatic cells are characterized by their elevated energy densities and excel in applications where optimizing space is paramount, rendering them an ideal choice for compact vehicles.EV Battery Modules: Challenges

As electric vehicle battery technologies advance, the EV battery module landscape must overcome challenges such as cost, energy density, weight, charging speed, charge range, and battery degradation. Despite improvements in fast charging technologies, reducing charge times without compromising battery health remains a challenge to effectively compete in the market. Therefore, developing compact battery pack designs, effective thermal management, enhanced energy density, and robust battery management systems are critical to prolong battery lifespan.Ruggedize Batteries to Withstand Environmental Exposure

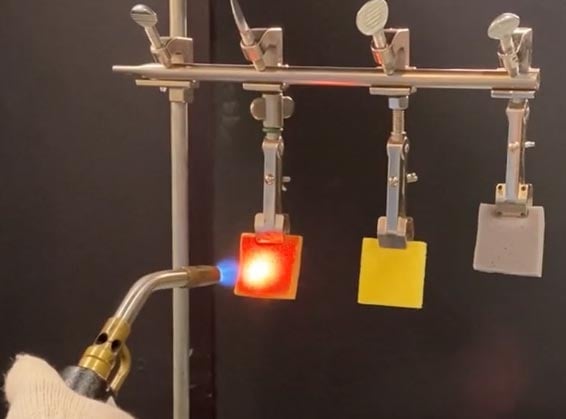

(View transcript)

Boyd’s Innovative Solutions for EV Battery Modules

Thermal Management

Boyd’s cutting-edge cooling technologies efficiently dissipate heat and prevent thermal runaway, without adding excessive weight or size to the EV. Our advanced liquid cooling systems and customized cold plates efficiently manage battery heat to prolong battery lifespan and enhance overall performance.

Insulate and Shield

Boyd excels in the specifying and fabricating integrated flame barrier materials that confine flames within a battery. Flame barriers are essential to isolate catastrophic events and prevent thermal runaway propagation. Boyd’s compression pad technologies protect cells against mechanical shock or impact, minimize sparking or shorting issues, maintain thermal contact for cooling, and limit heat-generating friction.

Seal and Protect

Effective seals and gaskets are paramount to achieve ingress protection, impact resistance, and optimal thermal management in EV battery assemblies. Boyd guides customers in selecting ideal materials, including pressure-sensitive adhesives (PSAs), high-performance foams, and durable elastomers, to craft battery module gaskets and port seals meeting critical needs. Our custom-fabricated PSAs, such as VHB tape, adhesive transfer tape, and various double-sided PSA tapes, are skillfully employed to secure environmental seals and gaskets to battery modules or ports.Innovate with Boyd

Boyd has decades of experience and expertise delivering thermal, insulation and shielding, and sealing and protection solutions for the eMobility industry. We have a track record of shipping over a billion eMobility components and installed our technologies in over 2 million eMobility vehicles. Leverage our 60+ years of automotive heritage for proven reliability and quality. Boyd’s rapid prototyping and design iterations accelerates time to market.

Our advanced liquid cooling and material science expertise enable us to incorporate multiple capabilities into vertically integrated eMobility solutions. To learn more about our EV Battery solutions or to discuss your project needs, schedule a consultation with our experts.