Air to Air Heat Exchangers

An air to air heat exchanger transfers heat and cools hot airflow with a secondary separate cold air stream to remove heat from an enclosure.

Transferring Heat from One Air System to a Second

Air to air heat exchangers are an effective way to transfer heat between two separate air systems, whether it’s moving heat from inside an enclosure to ambient air or from one enclosed air system to another. Heat exchangers are essential when the internal environment generates heat, but must be protected from external conditions.

Have a Question?

What is an Air to Air Heat Exchanger?

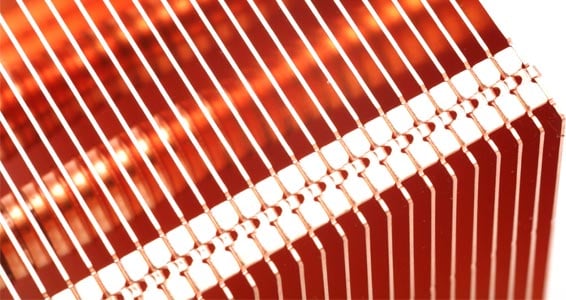

Air to air heat exchangers are a thermal management solution that has two sets of fins and a method that thermally joins those two sets of fins. Each set of fins are separated from each other with an air blocker that seals the two separate airflows from each other.

How do Air to Air Heat Exchangers Work?

Air to air heat exchangers absorb heat from the hotter air flow through a set of fins. This set of fins conducts heat into the heat exchanger. Heat is transferred from one set of fins through the heat exchanger using either conduction or passive two phase systems like heat pipes or vapor chambers. The second set of fins heat up and then conduct heat into the second air flow

Air to Air Heat Exchanger Fabrication

Effectively transfer heat from one air system to another using Boyd’s Air to Air heat exchangers. Boyd’s air to air heat exchangers leverage high conduction materials or passive two phase systems like heat pipes or thermosiphons to transport heat from one side of the heat exchanger to the other.

To fabricate our air to air heat exchangers, our engineers leverage a variety of in-house construction methods including folded fin fabrication, zipper fin production, nickel plating, heat pipe manufacturing, vacuum brazing, dip brazing, soldering, and welding. Our team can mix and match the best fit technologies to meet your specific application requirements.

Meet Application Requirements with the Right Construction

Boyd’s broad air cooling technology portfolio demonstrates our deep expertise and heritage that you can leverage to maximize reliable thermal performance in any application.

Thermosiphon Heat Exchangers

Thermosiphon heat exchangers use gravity to passively transport heat from the hot air side of the heat exchanger to the cold side. Boyd’s air and two-phase engineering expertise paired with quality manufacturing enable us to produce reliable, high capacity thermosiphon heat exchangers.

Aerospace Aftermarket Replacement Heat Exchangers (Re-Cores)

Extend the lifetime of your advanced heat exchanger system by replacing the internal heat exchanger surfaces with a cost-effective re-core for low cost system retrofitting. Boyd is also known for reverse engineering original equipment for aftermarket heat exchanger core replacements. Extend the lifetime of your heat exchanger systems with our recore solutions, reduce overall lifetime spend and optimize maintenance for your system.

Have questions? We’re ready to help!