PCR Diagnostics/ Microfluidic Diagnostic Laminates

Why Boyd for PCR Diagnostic Solutions?

Reduce Time and Cost

Enable faster and more accessible health care diagnosis and treatment decisions.

Rapid Prototyping

Turn around complex samples quickly and reduce your design cycle time.

Cost-Effective

Maximizing material yield and minimize waste with efficient manufacturing techniques.

Microfluidic Diagnostic Laminates

Microfluidic Diagnostic Laminates, or Lab-on-a-Chip Devices, are an optimized method for medical testing that require less fluid and materials. Microfluidic Diagnostic Laminates feature layers of innovative specialized materials and precise fluid channels to control the reaction of patient samples to chemical reagents. This is a miniaturization of what used to require an entire medical lab to complete and has earned this medical breakthrough the name “Lab-on-a-Chip”. This mobile diagnostic tool reduces the time and cost to detect pathogens or genetic disorders, enabling faster and more accessible health care diagnosis and treatment decisions.

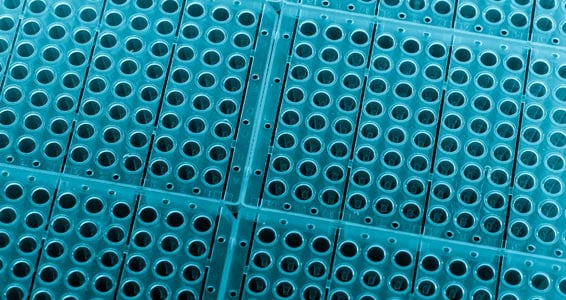

Polymerase Chain Reaction Testing

Polymerase Chain Reaction (PCR) Testing is also a critical aspect in the Microfluidic Diagnostic process. PCR Plates help manage hundreds of small samples in an array of fluid wells. PCR Test Plates are a necessary tool in containing and preserving these samples to ensure accurate and reliable diagnostic testing. Miniaturizing sample storage with efficient PCR Plates reduce handling by lab technicians and the overall time required to manage hundreds of tests.

Medical Laminates and Seals

The success of Microfluidic Diagnostic Laminates and PCR Plate Seals rely on selecting the right medical adhesives and material laminates to enable fluid flow through the device. By using a combination of adhesives with hydrophobic or hydrophilic substrates and films, Microfluidic Diagnostic Laminate designers move or seal fluid in a controlled manner to mimic established lab practices on a microscopic scale in a small plate or test strip. Reflective materials like aluminum film and optically clear adhesives assist in visual detection systems to further streamline the diagnosis process.

Medical laminates are enabled by medical precision converting capabilities as the vital role in fabricating reliable Microfluidic Diagnostic Laminates. The Lab-on-a-Chip device relies on accurate fluid path geometry, reliable adhesion between layers, and elimination of and protection from contaminants. PCR Plates require an effective film or foil to safely contain and consistently preserve samples. PCR Plate Seals can feature reusable or permanent adhesives with strong or pierceable films. Process consistency and certified clean rooms are a Medical Converter requirement to produce reliable Microfluidic Diagnostic Laminates.

Boyd Clean Rooms and Process Control

Boyd leverages our world class precision converting capabilities available in clean rooms certified from 100 to 100k, stringent ISO 13485 certified QMS processes and procedures, and our vast medical material science expertise to enable our Medical Converting engineers to design and fabricate PCR Plate Seals and Microfluidic Diagnostic Laminates as a fully outsourced and packaged medical solution.

Medical Material Expertise at Boyd

Boyd’s material expertise includes medical and skin contact approved adhesives, medical grade woven and non-woven fabrics, thin film plastics, metal foils, foams, and more. Microfluidic Diagnostic Laminates are now blending technologies with medical wearable devices, disposable sensors and wearable patches. Boyd is well-versed in disposable medical wearable assembly applications and can help you integrate these capabilities into a single device. Boyd’s in-house rapid prototyping capabilities help turn around complex samples quickly, reducing your design cycle time so you can test and validate your Lab-on-a-Chip or PCR Plate Seal design faster.

Boyd’s Medical Precision Converting Expertise

Boyd’s ability to cleanly handle the most challenging medical adhesives and other laminate materials in our multi-station, high volume rotary die cutting processes enable us to laminate up to 10 complex layers in a single operation. We rely on decades of process experience and innovation to maximize material yield and minimize waste, crucial to optimize end device cost when manufacturing expensive medical grade raw materials.

Boyd also has specialized processes to integrate microelectronic components into more advanced Microfluidic Diagnostic Laminates for smart operation or device tracking. By partnering with Boyd, we fabricate for you advanced, precise, and reliable Microfluidic Diagnostic Laminate devices and PCR Plate Seals in the most cost-effective manner possible, fully outsourced within existing ISO 13485 certified operations able to quick turn sampling, prototyping and mass production to exceed your time to market goals.

Microfluidic Diagnostic Laminate Solutions

- Decrease expensive chemical reagent usage by reducing required amount for each test

- Find answers faster by integrating multiple lab processes in a single test strip

- Reduce personnel load by simplifying testing procedure with miniaturization

- Increase testing accessibility with mobile-friendly lab kits

- Integrate with microelectronics and Near Field Communication (NFC) for smarter medical diagnostic tools

- Leverage optically clear adhesives to streamline visual detection processes

- Combine with sterile kitting for complete diagnostic test kits

- Utilize conformable, skin compatible materials for wearable diagnostic patches

Microfluidic Diagnostic Laminates Materials

Boyd’s engineering team works closely with your design teams to select optimized materials that meet your exacting application requirements. Boyd leverages close relationships with our medical material suppliers to get you the best fit material to meet your project’s functional needs and cost targets. We design ISO1385 compliant manufacturing processes to fabricate and assemble your design for you — transforming medical covers, lidding tapes, spacer tapes, adhesives, and substrates into functional Microfluidic Diagnostic Laminates.

- Adhesives:

- Acrylic

- Silicone Acrylic

- Substrates:

- Polyester

- Polyolefin

- Aluminum Foil

- Substrate Coating Options:

- Hydrophilic – single or double sided

- Hydrophobic – single or double sided

- Material Characteristics and Requirements to Consider:

- Mammalian Cell Compatibility

- Non-Hemolytic

- Low Extractables

- Clouding Resistance

- Autofluorescence

- Outgassing

Have questions? We’re ready to help!