Protecting Aluminum: Anodizing and Chromate Coatings

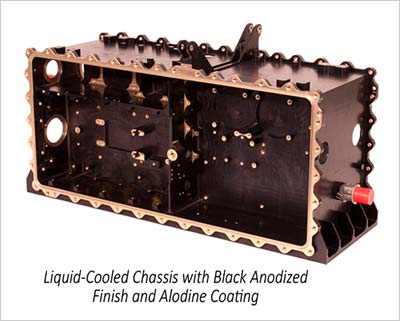

Enhance aluminum components with specialized coatings. Specialized coatings can make aluminum parts more durable or boost aluminum’s natural characteristics and benefits. Safeguard aluminum parts with finishes like anodizing and chromate coatings offers unique advantages. These finishes enhance the durability and functionality of aluminum, ensuring aluminum parts meet the rigorous demands of different applications. Boyd excels in offering both anodize and chromate coatings, leveraging our expertise to deliver high-quality solutions tailored to your needs.Chromate Coatings: Preserving Conductivity

Chromate coating is a chemical conversion process that enhances aluminum’s natural corrosion resistance without adding significant thickness. The process starts with cleaning and etching the aluminum surface to remove the natural oxide layer. The part is then submerged in a chromate bath, where the chemical solution bonds with the aluminum, forming a thin, corrosion-resistant film. This coating is beneficial to maintain aluminum’s electrical and thermal conductivity while delivering necessary corrosion protection.

Chromate Coating Solutions: Type I and II

Boyd adheres to the MIL-DTL-5541 specification for chromate coatings, offering both Type I and Type II options. Type I uses hexavalent chromium, offering robust corrosion resistance, while Type II is a RoHS-compliant, trivalent chromium option that meets modern environmental standards. Each type is further classified into Class 1A and Class 3, with Class 1A providing a thicker, more protective coating, and Class 3 offering better electrical contact resistance with a lighter, more translucent finish.Chromate Coatings for Bonded Assemblies

Chromate coatings excel in bonded assemblies, maintaining aluminum’s natural conductivity and adhesion properties. They benefit components that require minimal thickness while still offering corrosion protection. Boyd leverages these benefits to ensure that your aluminum parts meet the highest standards of performance and reliability.

Anodizing: A Protective Process

Anodizing is an electrochemical process that enhances the natural oxide layer on aluminum, creating a durable and corrosion-resistant surface. During anodizing, a current passes through the aluminum part, causing the surface to oxidize and form a thick, protective layer. This layer offers superior corrosion resistance and dyes in diverse colors, making anodizing an excellent option for applications where both protection and aesthetics are essential.Anodized Finishes for Commercial Applications

Boyd specializes in Type II, Class 2 anodizing, used for black anodized finishes. This process is ideal for aluminum assemblies, delivering a tough, corrosion-resistant surface with a sleek, uniform appearance. Our expertise in black anodizing meets the stringent standards for commercial products, ensuring your parts are both protected and visually appealing. We also offer Class 1 (non-dyed) anodizing for a clear finish.