O-Rings: Effective Sealing Solutions

O-Rings are primarily static seals used to prevent leaks or provide cushion between two opposing surfaces compressed together.

Prevent Fluid and Particle Ingress

Seal out against water, dust, or air to maintain controlled internal environments.

Increase Reliability

Reduce the impact of noise, vibration, harshness, and shock on your product.

Improve Product Lifetimes

Reduce wear and tear between sealed surfaces with durable o-rings.

O-Ring Seals for Improved Reliability and Lifetime

O-Rings are a common, yet critical component in dynamic and static assemblies in every industry. Having access to a fast and reliable supply of standard O-Rings helps shorten design and maintenance cycles, improve uptime and time-to-market, and minimize costs.

Have a Question?

What Are O-Rings?

O-rings are a type of mechanical seal used to prevent fluid leakage between two mating surfaces. O-rings are torus-shaped rings typically made from elastomers, such as rubber or silicone, although other materials like plastics, metals, and thermoplastics can also be used. The name “O-ring” comes from the ring’s circular. There are ring seals with different cross sections such as square rings, X-rings, U-rings, and V-rings for more specific applications.

How Do O-Rings Work?

When compressed between two surfaces, the O-ring deforms to fill any irregularities or gaps, creating a tight and reliable seal.

Why Use Boyd O-Rings?

Boyd offers excellent on-time delivery, short lead times, high quality, and great customer service in the O-Rings industry. Boyd’s engineered material experts identify with you the best compound, dimension, finish, filler, and configuration to optimize the sealing performance of o-rings, axial seals, and radial seals within your application. Our available engineered materials library for o-rings and molded seals includes more than 600 elastomeric compounds including silicone, fluorocarbon, nitrile (Buna-N), ethylene propylene diene monomer (EPDM), and many others in both standard AS568 sizes and custom designs.

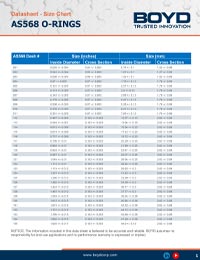

Boyd’s Standard O-Ring Support

O-Rings.com by Boyd stocks every standard AS-568 O-Ring size in 8 common elastomeric compounds, enabling us to deliver dependable seals immediately. With the highest quality, most timely shipments, and best customer service, Boyd is an ideal partner and O-Ring supplier.

Boyd’s Custom O-Ring Support

Boyd’s o-ring solutions offer both quick service and delivery of standard options for quick-turn needs and custom seal design for more complex performance or assembly challenges. Boyd’s engineering team partners with you to help select a compound, assist with design, and provide technical support to create the most optimal radial seal, o-ring or axial seal for your unique application. Our o-rings are manufactured in operations with ISO9001, ISO13485, IATF16949, AS9100C, or ISO14001 certified quality and environmental management systems to assure our sealing solutions exceed the quality and environmental specifications for both general industry and specialized markets like medical, automotive and aerospace.

Standard O-Ring Compounds

| Compound | Description | Temperature Range (°F) | Temperature Range (°C) | Durometer (Shore A) | Color | FDA* Approved | Data Sheet |

|---|---|---|---|---|---|---|---|

| N100-70 | General purpose, sulfur-cured Nitrile (Buna-N) | -40 to +250 | -40 to +121 | 70 | Black | No | N100-70 Technical Report [PDF] |

| N168-70 | FDA Grade, Nitrile (Buna-N) | -40 to +250 | -40 to +121 | 70 | Black | Yes | N168-70 Technical Report [PDF] |

| N140-90 | A sulfur-cured, Nitrile compound for high pressure | -40 to +250 | -40 to +121 | 90 | Black | No | N140-90 Technical Report [PDF] |

| V700-75 | DuPont Viton®, with exceptional chemical resistance | -20 to +400 | -28 to +204 | 70 | Black | No | V700-75 Technical Report [PDF] |

| V708-75 | DuPont Viton®, with exceptional chemical resistance | -20 to +400 | -28 to +204 | 75 | Brown | No | V708-75 Technical Report [PDF] |

| V768-75 | FDA & 3A Sanitary Grade. DuPont Viton®, with exceptional chemical resistance | -20 to +400 | -28 to +204 | 75 | Brown | Yes | V768-75 Technical Report [PDF] |

| S500-70 | FDA Grade Silicone compound for food & medical applications | -20 to +400 | -28 to +204 | 70 | Red | Yes | S500-70 Technical Report [PDF] |

| E300-70 | FDA Grade EPDM compound for ozone, water & UV service | -65 to +300 | -54 to +149 | 70 | Black | Yes | E300-70 Technical Report [PDF] |

*FDA per CFR 177.2600

Advanced O-Ring Compounds

All Boyd O-rings are built to the highest national and international safety standards. Our rigorous adherence to these industry and governmental standards ensures the highest-quality O-rings and custom-molded seals delivered to distributors and manufacturers.

Boyd has recently developed two unique compounds specially-formulated for potable water applications requiring NSF standard 61 approval.

NSF Standard 61 Approved O-Rings

The NSF Water Distribution Systems Program is responsible for the certification of drinking water treatment chemicals and drinking water system components to ensure that these products do not contribute contaminants to drinking water that could cause adverse health effects.

NSF Standard 61 Drinking Water System Components – Health Effects is the nationally recognized standard for all devices, components and materials which contact drinking water.

| Compound | Description | Temperature Range | Durometer (Shore A) | Color | FDA Compliant |

|---|---|---|---|---|---|

| N161-70 | A general purpose, sulfur-cured NSF Standard 61 Approved Nitrile (Buna-N) compound | -40 to +250F | 70 | Black | Yes |

| E362-70 | NSF Standard 61 Approved peroxide cured EPDM | -65 to +300F | 70 | Black | Yes |

FDA Approved O-Rings

Boyd has formulated a wide range of O-Ring materials to exceed the Food & Drug Administration’s (FDA) requirements for synthetic rubber compounds. All of our FDA compounds used in FDA approved O-Rings or as a FDA seal conform to the Code of Federal Regulations section 177.2600.

| Compound | Description | Temperature Range | Durometer (Shore A) | Color |

|---|---|---|---|---|

| N168-70 | FDA Grade Nitrile (Buna-N) | -40 to +250F | 70 | Black |

| E300-70 | FDA Grade EPDM | -65 to +300F | 70 | Black |

| S500-70 | FDA Grade Silicone | -80 to +400F | 70 | Black |

| V760-75 | FDA Grade Silicone | -20 to +400F | 75 | Black |

| V768-75 | Dupont-Dow Viton®, FDA Grade | -20 to +400F | 75 | Brown |

| C268-70 | FDA Grade Neoprene | -40 to +225F | 70 | Black |

| N188-70 | FDA Grade, UltraSlip® Nitrile | -40 to +250F | 70 | Black |

| E388-70 | FDA Grade, UltraSlip® EPDM | -65 to +300F | 70 | Black |

WRAS Approved O-rings

Water Regulations Advisory Scheme (WRAS Standard) is responsible for the water fitting testing and approval process in the United Kingdom. This organization specifies performance criteria and test procedures designed to verify compliance to British WRAS standard for product use with water fittings.

| Compound | Description | Temperature Range | Durometer (Shore A) | Color |

|---|---|---|---|---|

| E363-70 | WRAS Approved for use in British and UK water fittings | -65 to +300F | 70 | Black |

KTW Approved Orings

KTW Guidelines are formulated by the German Technical Association for Gas and Water. These standards cover guidelines for organic materials that come into contact with drinking water intended for human consumption. Test procedures and migration criteria are provided in the KTW guidelines as a means of determining whether a material meets threshold heath, odor, and flavor requirements.

| Compound | Description | Temperature Range | Durometer (Shore A) | Color |

|---|---|---|---|---|

| N163-70 | KTW Approved for European Drinking Water Systems | -40 to +250F | 70 | Black |

Have questions? We’re ready to help!