Benefits of Boyd’s Value-Added Assemblies

With shrinking time-to-market to create complex assemblies, how do you simplify logistics, mitigate soaring design development costs, and remain agile? At Boyd, we take a holistic approach to building your device. From the manufacture of individual components to the complete assembly, you get a plug-and-play tested assembly that you know will function as intended. Our expertise in a variety of technologies consolidates your supply chain and results in streamlined shipping, accounting, and auditing functions for our clients.Consolidate Supply Chain and Operations

Reduce Overall Costs While Providing More Value

Faster Time-to-Market

Streamline Manufacturing and Boost Bottom Line Efficiency

Developing a device with multiple suppliers and manufacturing facilities with varying quality control can be a risky and expensive ordeal. By integrating multiple functions into a single component, we help mitigate costs, reduce assembly time and BOM complexity while reducing the number of vendors you need to manage. You’ll get custom-engineered solutions to fit your project requirements. Our streamlined manufacturing and operations eliminate the hassle of searching for the perfect component or vendor and helps you avoid costly mark-ups and delays.

Innovating Solutions on Every Level

Boyd’s broad expertise of manufacturing processes, engineered materials, joining processes, and assembly enable simplification of complex designs and components. Our supplier relationships and internal capabilities provide increased control, predictability, and lower costs for your supply chain. We work closely with design teams to determine functionality requirements and find ways to create single, multifunctional deliverables that are ready for installation in both manual and automated production lines.

Boyd Spotlight Series – Estimator Program Manager

(View transcript)

Drive Efficiency

With an escalating need to drive efficiency, it’s time to think beyond component manufacturing and find the complete “value” in value-added assemblies.

Contact us to learn more about Boyd’s techniques and processes for:

- Design Simplification to increase functionality in fewer components with advanced material selection and converting technologies

- Advanced Assembly techniques that enable us to produce complex assemblies with ultra-tight tolerances

- Complete Solutions that integrate Sealing, Thermal, Protection, and Identification into a single cohesive system or deliverable

Window Assemblies

Boyd is long experienced in stylish and durable transportation window assemblies and glass systems. With strong design support and expertise in both molded plastic and bent aluminum extrusion frames, Boyd’s expert design teams work with you to create a trusted solution customized for your specific application.

Long Term Functionality and Performance

Practical, modern and intricate designs provide visibility, functionality and reliable long term performance. Solutions include a wide variety of design potentials for a window assembly from frameless windows, sliding windows, RV windows, stationary glass and unique shapes.

Wide Range of Window Options

Window assemblies include a wide variety of finishing options for the ultimate in customizations – from various bug screens to durable seal technologies and latch and lock mechanisms. Boyd’s windows, custom designed to exceed your specific performance and style needs, will uphold your rigorous branding and image standards while delighting your customers for the long haul.

Customizable

Cost-Effective

Environmental Protection Assemblies

Thermal Assemblies

Leverage the breadth of Boyd’s thermal technologies into a single thermal management solution. Boyd’s equipped to manufacture complete liquid systems utilizing liquid cold plates, heat exchangers, tubing, pumps, quick disconnects, and control systems for your high performance cooling requirements. Or utilize ambient air to its’ fullest potential with thermal fans and blowers combined with heat exchangers, thermosiphons, or enhanced heat sinks with heat pipes and vapor chambers.

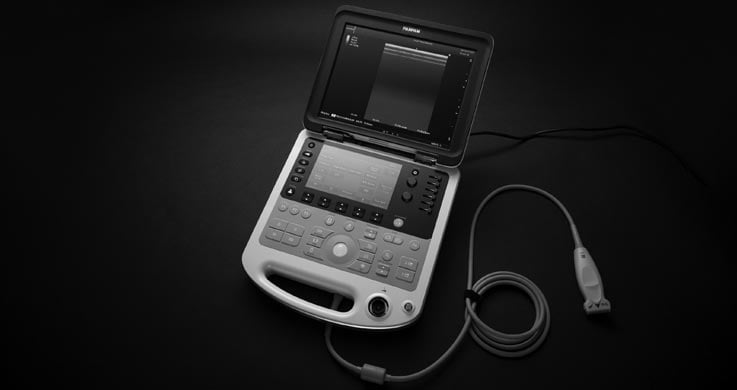

Electro-Mechanical Assemblies

Whether you are looking for labels, graphic overlays, die-cut components, or backlighting options, or user switches and interfaces you’ll get custom-engineered solutions to fit your every need, big and small. With faster time to market and increased quality control, our electro-mechanical assemblies will provide you with a more reliable and streamlined supply chain.

Plastic & Metal Housings & Chassis

Coextrusion, Encapsulation, & Overmolding

Boyd’s injection molding and extrusion processes enable us to enhance the performance and functionality of your assembly to help you streamline production and reduce overall costs. Insert components into rubber or plastic for added protection, functionality, or product simplicity. Boyd can overmold metals or rigid plastic in conformable rubbers for user safety, comfort, and protection against scratching and punctures. Encapsulation within high quality rubbers protects components like electronics and sensors against environmental risks. Fabric, mesh, or wire inserts in multi-durometer coextrusions add functionality, durability, and performance to our profiles, tubes, and tube sets.

Kitting & Packaging

Kitting helps end users install or maintenance products by including all key components together in a single package. Sourcing multiple components and kitting them into a single package reduces time spent collecting parts from inventory, reduced confusion of matching components, and streamlines the assembly process.

Have questions? We’re ready to help!