Adhesive Tapes: Bonding Solutions

Tapes are comprised of specialized adhesives in varying formats optimized for a wide variety of applications. They revolutionized the ability to join and assemble components quickly in industrial manufacturing, electronics devices, medical applications, automotive assemblies, labeling and virtually every other industry.

Fast Assembly and Installation

Pressure sensitive tapes make it easy and efficient to install and assemble components in any device.

Stick to Difficult Surfaces

Specialty low surface energy tapes allow you to bond to surfaces that are tough to adhere to.

Formatted for Any Application

Double coated tapes that aid in tolerance control during installation or free form tapes that give you flexibility.

Boyd & 3M present: Will it Stick?

(View transcript)

Precision Die-Cutting Solutions

(View transcript)

Wide Variety of Available Tapes

Tape applications vary greatly, so there is a wide variety of tapes with drastically different scientific formulations and mechanical presentations optimized for different uses. Surface energy compatibility, temperature range, conformability, adhesive strength, peel strength, shear strength, push-out strength, reusability, permanent bonding, and environmental resistance are just a few variable factors available to customize tape performance. Add to that the infinite customization possibilities in how these tapes can be fabricated to fit your unique applications can make selecting and designing an optimal tape solution overwhelming.

Have a Question?

What Are Tapes?

Tapes are adhesive materials that can either be in sheets or rolls and are used to bond two surfaces together. Tapes come in a wide variety of material compositions and styles to meet nearly any application requirement.

What Are Pressure Sensitive Adhesives?

Pressure sensitive adhesive tape features adhesive formulations that bond with nominal applied pressure for efficient and reliable permanent or reusable securement. Pressure sensitive adhesive tape is sometimes called PSA tape and is available in multiple formats and constructions.

Why Use Boyd for your Tape Solutions?

We have worked closely for more than 70 years with our strategic supply partners who are the world’s greatest innovators in tape and adhesive formulations. We understand the science of applying these innovative tape formulations into your custom designed applications. We help you select the right formulation for your performance requirements and intended use environments then use industrial design for manufacturing methodologies to assure your components are manufacturable, within your design tolerances, and delivered in a custom configured format optimized for automated or hand assembly into your application. We help you translate adhesive science into real components optimized for cost and performance throughout your value chains.

Varying Styles for Specific Application Needs

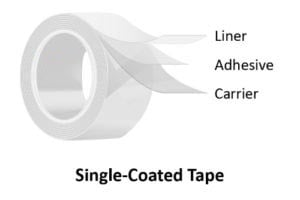

Adhesive tapes are built using a combination of three components: the adhesive, carrier material or backing material, and the release liner. Adhesive transfer tapes, single coated or single sided tape, and double coated or double-sided tape are the most common tapes used in precision converting.

Adhesive Transfer Tapes

Adhesive transfer tapes, also called unsupported tapes or free film tapes, are pressure-sensitive adhesives pre-applied to siliconized paper or film release liner. Adhesive transfer tapes are used for a variety of bonding, mounting, splicing, laminating, and closure applications in a wide range of industries. Adhesive transfer tapes are conformable, flexible, stick quickly, and demonstrate good adhesive wet out, shear strength, and holding power at elevated temperatures.

Single-Sided Adhesive Tape

Single sided tape refers to a carrier or backing material coated with an adhesive only on a single side. Single sided tape is great for bonding, sealing, splicing, protecting, masking, and identification solutions in a wide range of industries.

Double Sided Adhesive Tape

Double sided tape is coated with adhesive on both sides of a carrier material. The adhesives can but do not have to be the same on both sides. When double sided tape is used to bond different, dissimilar materials together and features different adhesives on each side of the tape, it is called differential adhesive tape. Double sided adhesive tapes are used for a wide range of applications including bonding, mounting, splicing, and packaging applications across a wide range of industries. Manufacturers are continuing to replace mechanical fasteners and rivets with double sided tapes, especially in the transportation industry.

Carrier Types

Adhesive tapes use flexible materials as a carrier or backing material and there is a wide variety of tape backings to choose from. Potential tape carrier materials include fabrics, either woven cloth or non-woven materials, films, foams, foils, paper, or rubber.

Adhesive Types

Adhesives come in a wide range of chemical compositions. The most common adhesives include acrylic-based, rubber-based, or silicone-based adhesives. Acrylic adhesives can be either water-based, solvent-based, or pure acrylic, provide excellent environmental resistance and are used on a variety of surfaces. Rubber-based adhesives are divided into natural and synthetic rubber, best for indoor applications. Silicone adhesives are more expensive but exhibit excellent high-temperature performance and chemical resistance.

Have questions? We’re ready to help!