EMI Shielding and Management

Electromagnetic Interference (EMI) can drastically impact electronic device performance and reliability, requiring EMI shielding and absorbers to protect sensitive components.

Increase Device Density

Eliminate crosstalk between components and place more electronics in smaller volumes without risking electronic signal corruption.

Maintain Signal Integrity

Prevent internal EMI and RFI from distorting electronic communications.

Improve Device Sensitivity

Reduce extraneous electromagnetic signals to enhance transmit/receive modules.

What Goes Into Making Advanced Display Solutions

(View transcript)

EMI/RFI Shielding: Protect Product Performance and Reliability

Effectively manage errant electromagnetic waves with EMI/RFI Shielding solutions. While a Faraday cage made of continuous conductive material is the ideal solution, product designs often pose challenges. Engineers address this by incorporating EMI shielding and absorption components strategically in openings, gaps, and seams within a device. These components serve as barriers to unwanted external energy, containing internal electromagnetic waves for improved performance.

Have a Question?

What Is EMI (Electromagnetic Interference)?

Electromagnetic interference (EMI) is electromagnetic signal disturbance caused by electronic devices or communication systems. It can manifest as noise, glitches, or signal degradation, leading to undesirable effects such as data corruption, decreased performance, or even complete system failure.

What is RFI (Radio Frequency Interference)?

Radio Frequency Interference (RFI) is the disturbance caused by unwanted radio frequency signals that interfere with the proper functioning of wireless communication systems or electronic devices.

Where Does EMI and RFI Originate?

Electromagnetic interference and radio frequency interference signals originate from other nearby electronic devices, power lines, or atmospheric phenomena. Conductive surfaces, like wires or metallic enclosures, generate unexpected current and electrical energy when exposed to electromagnetic waves that come from a wide variety of both natural and artificial sources. Uncontrolled natural and artificial energy waves enter or exit an electronic device through seams and openings in the device and cause erratic signals, impacting performance.What Is EMI Shielding?

Electromagnetic Interference (EMI) shielding reduces or eliminates undesirable electromagnetic radiation effects on electronic devices or systems. EMI Shielding uses materials or techniques that create a barrier to block or redirect electromagnetic waves, preventing them from interfering with sensitive components. EMI shielding maintains device integrity and performance by minimizing the impact of external electromagnetic fields and ensuring electromagnetic compatibility (EMC).

How Does EMI/RFI Shielding Work?

EMI/RFI shielding materials, such as conductive metals or conductive coatings, create a barrier between the electronic device and external electromagnetic fields. These materials act as a shield, reflecting or diverting electromagnetic waves away from sensitive components and preventing EMI penetration into the device. Shielding effectiveness depends on factors like material conductivity, thickness, and the frequency range of the interfering signals.What are EMI Absorbers?

Address electromagnetic interference effectively with EMI/RFI Shielding solutions. Electromagnetic Interference absorbers, also known as EMI absorptive materials or absorptive filters, are specialized materials designed to absorb or attenuate electromagnetic radiation. EMI absorbers mitigate electromagnetic interference effects on sensitive devices and systems. EMI absorbers are often used in shielding applications to enhance the electromagnetic compatibility of electronic components and improve overall system performance. EMI absorbers are typically used when shielding alone is not sufficient or where reflection of EMI waves may cause further interference.

How Do EMI Absorbers Work?

Efficiently manage EMI interference with EMI/RFI Shielding solutions. EMI absorptive materials are designed to absorb and dissipate electromagnetic energy as heat rather than reflecting or transmitting it. By converting electromagnetic energy into heat with conductive or magnetic materials, EMI absorbers effectively reduce the intensity and impact of EMI interference.Why Use EMI Shielding and Absorbers?

EMI/RFI shielding, and absorbers reduce electronic signal integrity and strength which can cause errors and reduce performance in sensitive communication systems and devices. Seams and openings in electronic devices provide avenues for unwanted energy waves to enter or exit a device, causing erratic performance. EMI/RFI shielding seals these seams from EMI signals. EMI absorbers are often used in shielding applications to enhance the electromagnetic compatibility of electronic components and improve overall system performance. EMI absorbers are typically used when shielding alone is not sufficient or where reflection of EM waves may cause further interference.EMI/RFI Shielding Expertise at Boyd

Boyd’s team of Engineered Materials experts have designed highly effective, cost efficient, easy-to-use EMI/RFI shielding and absorbing solutions for many decades. Our material scientists help you select an EMI shielding material and assist with design to create the most optimal electromagnetic control solution for your unique device geometry and performance. Shielding materials are often combined with elastomeric materials for an integrated solution that offers excellent compressibility to maximize conductivity and contact.

Meeting Your Demanding EMI Requirements with Boyd

Boyd’s vast application experience and engineering support ensures your EMI challenges are solved in a cost effective, efficient way. Enhance customer satisfaction and safety, ensure regulatory approval, and reduce warranty claims with Boyd EMI management solutions. We strive to produce EMI shielding solutions that meet demanding requirements such as:- Environmentally compliant

- High shielding effectiveness

- Lightweight and recyclable

- RoHS compliant

- High electrical conductivity

- Various shielding effectiveness levels

Protect Components with the Right EMI/RFI Technology

EMI/RFI Shielding solutions balance electrical conductivity, dielectric permittivity, magnetic permittivity, and physical geometry to inhibit the transmission of EMI/RFI. Generally, shielding first deflects electromagnetic waves with reflective surfaces which then heats the shield, making moderate electrical and thermal conductivity important characteristics of an EMI/RFI Shield.

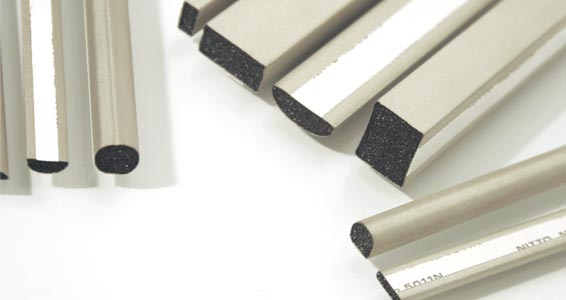

EMI/RFI Shielding Solutions: Fabric-Over-Foam

EMI/RFI shielding solution, fabric-over-foams are ideal for shielding applications that need high conformability, compressibility, and cushioning with low compression force. Boyd’s EMI/RFI gaskets are designed for electronic devices that need a soft cushion and tight contact with conductivity. Fabric-Over-Foam gaskets accommodate mechanical tolerance stack up with compliant and cushioning properties. Fabric-over-foam EMI gaskets offer high conductivity and shielding attenuation. Urethane and thermoplastic elastomer (TPE) cores provide low compression set ensuring long term gasket performance reliability. Metallized fabrics are available in nickel/copper (Ni/Cu) and tin/copper (Sn/Cu) to ensure galvanic compatibility with a wide variety of materials.

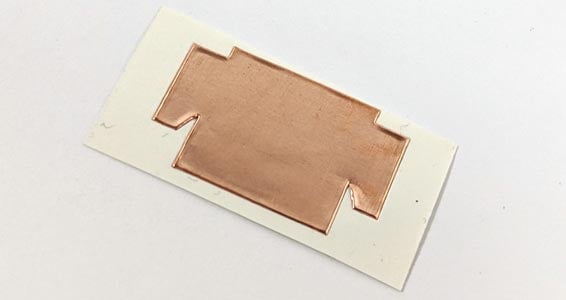

EMI/RFI Shielding Solutions: Foil Tapes

Precision converted foil tape EMI/RFI shielding helps reflect unwanted signals from critical components in highly customized shapes and configurations. Foils can easily be combined with other sheet materials like adhesives for easy installation or with other materials for added functionality.EMI/RFI Shielding Solutions: Conductive Foam Gaskets

Conductive foam gaskets are open celled foams impregnated with either conductive components or coated with carbon. With high electrical conductivity, flexible compressible conductive foam gaskets are a customizable EMI/RFI shielding solution to seal gaps against EMI and RFI signals.

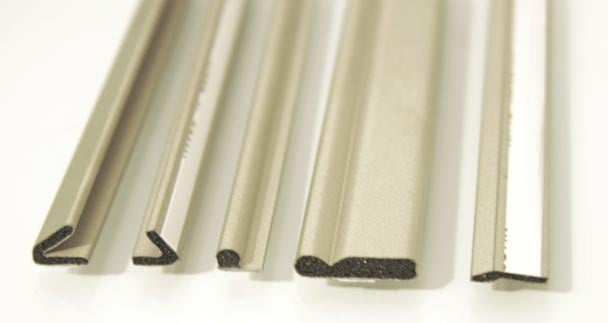

Finger Stock

Finger stock is ideal for conformable, compressible shielding performance in electronic devices that need tight, conductive contact. Cushioning accommodates mechanical tolerance stack up and electrical contact on various substrates. Finger stock EMI/RFI gaskets are typically made of either beryllium copper or stainless steel. Finger stock comes in a broad array of attachment methods such as snap-on, stick-on, clip-on, track, extrusion, weldable, and solderable.

Magnetic Particle Filled Polymeric Sheets (Flexible Ferrite)

Flexible ferrite, polymeric sheets filled with magnetic particles, act as an EMI/RFI absorber with high permeability, permittivity, and electrical conductivity and are ideal for high frequencies. This flexible sheet EMI/RFI shielding solution can be combined with other sheet materials like adhesives for easy installation. Flexible ferrite can be RoHS compliant, available halogen free, UL 94 flame rated, and NEMA flame rated options.

EMI/RFI Shielding Materials

EMI/RFI absorption solutions are customized to specific frequency ranges:

- General EMI noise absorption (1MHz – 10GHz, permeability from 20u’ to 200u’),

- RFID & WPC (1MHz – 3GHz, permeability from 20u’ to 70u’),

- Rigid NFC Ferrite (13.56MHz),

- WPC in a rigid format (125KHz, permeability from 140 u’ to 670 u’)

Common EMI/RFI Shielding Metals:

- Aluminum

- High conductivity

- High strength-to-weight ratio

- Non-ferrous

- Copper

- High conductivity

- Solderable

- Non-ferrous

- Copper Alloy 770/Nickel Silver, UNS C77000

- Corrosion resistant

- Solderable

- Permeability of 1

- Non-magnetic

- Pre-Tin Plated Steel

- Tin plating enables soldering

- Low cost

- Ideal for kHz to lower GHz range

Conductive Foam Materials:

- Foams:

- Silicone rubber

- Neoprene / polychloroprene or PC-rubber

- Urethane foam

- Ethylene-vinyl acetate (EVA)

- Polyethylene-vinyl acetate (PEVA)

- CR Sponge or chloroprene rubber (CR) foam

- Conductive Element:

- Embedded wires

- Metallic particulates

- Woven aluminum screen

Fabric-Over-Foam Materials:

- Cores:

- Urethane

- Thermoplastic elastomer (TPE)

- Fabrics:

- Nickel/copper (Ni/Cu)

- Tin/copper (Sn/Cu)

Finger Stock Materials:

- Beryllium Copper

- Broad frequency range

- High deflection range and fatigue resistance

- High conductivity

- High attenuation of over 100 dB

- Stainless Steel

- Good corrosion and heat resistance

- High spring strength

- Lower conductivity, attenuation, and cost

Have questions? We’re ready to help!